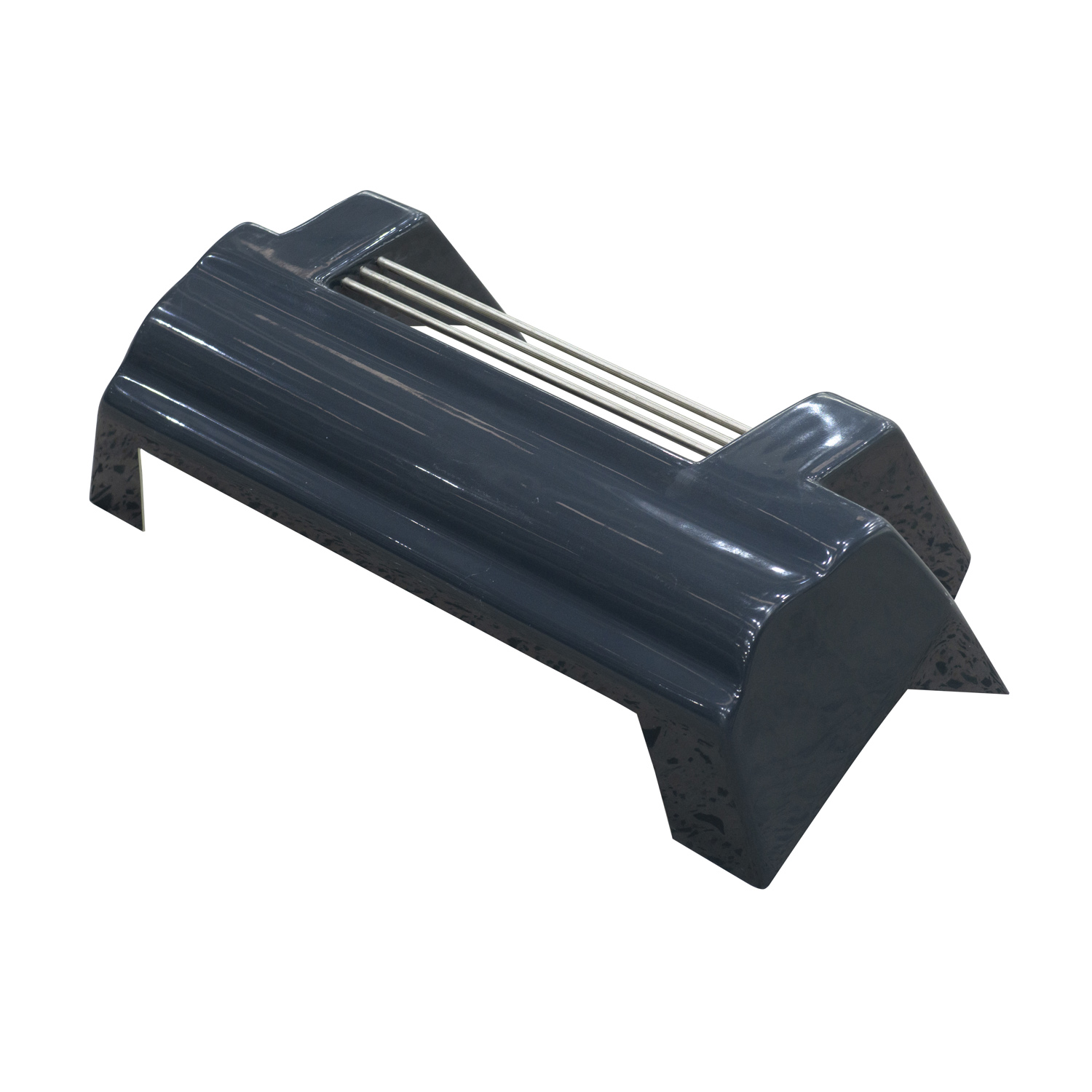

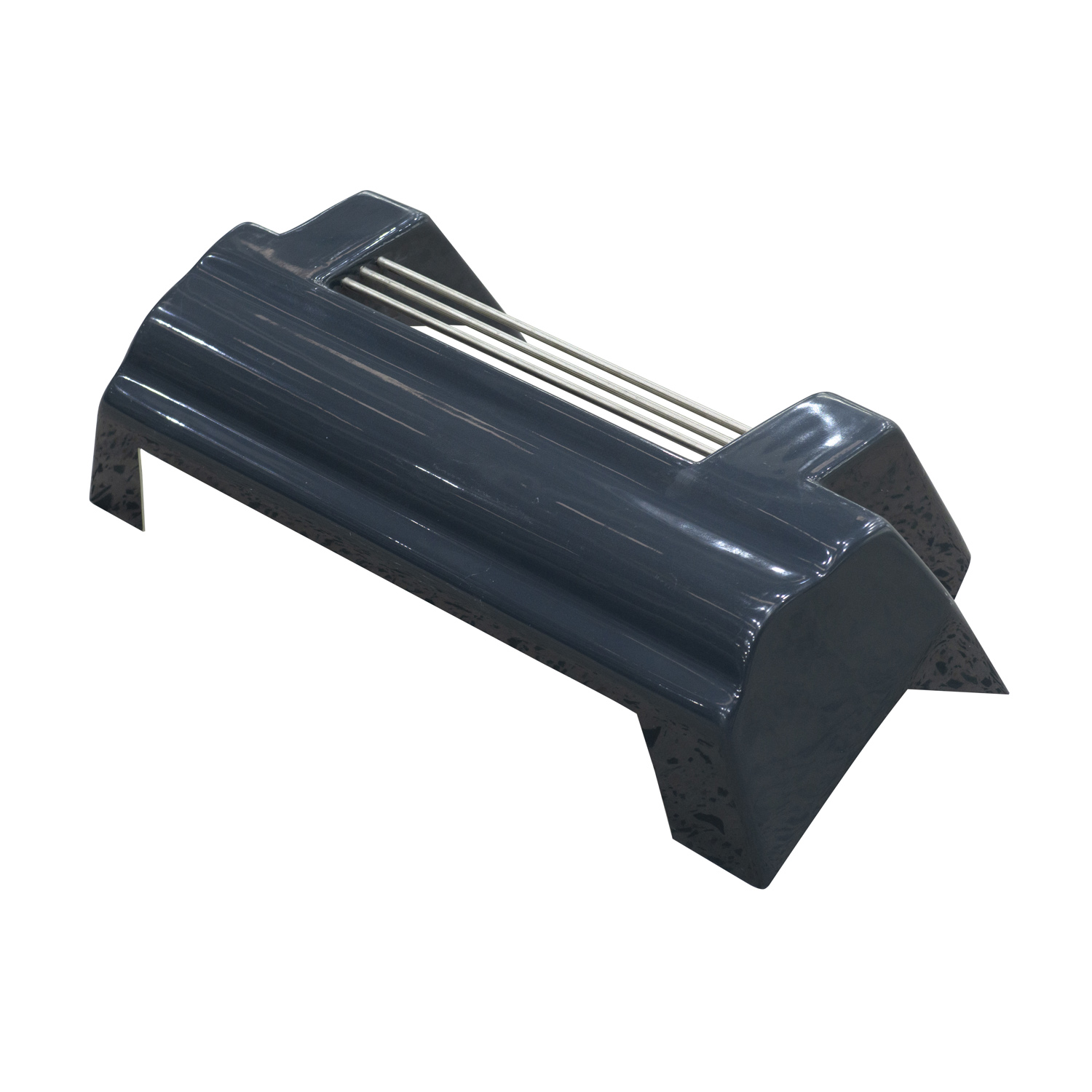

GRP Fiberglass Covers with Gel Coat for Construction represent a durable alternative to traditional timber, metal, or concrete covers in building projects.

| Availability: | |

|---|---|

| Quantity: | |

Composed of glass-reinforced plastic (GRP) with a protective gel coat finish, these covers offer exceptional weather resistance, structural stability, and low maintenance requirements. Designed to meet the rigorous demands of construction sites, they provide long-term performance in roofing, cladding, and infrastructure applications, outperforming materials prone to rot, corrosion, or warping.

Superior Weather Resistance

The high-quality gel coat surface undergoes extensive xenon arc weathering testing, demonstrating minimal deterioration even after prolonged exposure to sunlight, rain, and temperature fluctuations . Unlike unprotected GRP sheets, which develop fiber protrusions within months, these gel-coated covers remain smooth and intact for decades, with 50% better gloss retention than conventional finishes .

Structural Integrity

Reinforced with a woven glass fiber matrix, the covers achieve a compressive strength of 4309 Pa at 10% deformation, ensuring they withstand heavy foot traffic, equipment placement, and environmental stress . Their lightweight nature (30% lighter than concrete equivalents) simplifies installation, reducing labor costs and structural load on buildings.

Versatility and Safety

Available in custom thicknesses (2mm–10mm) and sizes, the covers accommodate diverse construction needs, from roof hatches to equipment enclosures. The non-conductive GRP material eliminates electric shock risks, while its slip-resistant texture enhances safety in wet conditions.

Commercial and Industrial Roofing

Ideal for covering skylights, ventilation units, and access panels on warehouses, factories, and office buildings, providing watertight protection against leaks.

Infrastructure Projects

Used in bridges, tunnels, and utility stations as protective covers for cables, pipes, and control boxes, resisting corrosion from saltwater and chemicals.

Residential Construction

Suitable for garden sheds, garages, and patio covers, offering a low-maintenance alternative to wood that won’t rot, splinter, or require annual painting.

What is the lifespan of GRP gel coat covers?

When properly installed, they have a service life of 20+ years in outdoor environments, significantly longer than timber (5–10 years) or uncoated metal (10–15 years).

Can the covers withstand extreme temperatures?

Yes, they perform reliably in temperatures ranging from -30°C to 90°C, making them suitable for both cold climates and desert regions.

Are they fire-resistant?

The GRP material is classified as self-extinguishing (UL94 V-0 rating), meeting international fire safety standards for construction materials.

How to clean and maintain the covers?

Routine cleaning with mild detergent and water is sufficient. No repainting or sealing is required, reducing long-term maintenance costs by up to 70% compared to wood.

Composed of glass-reinforced plastic (GRP) with a protective gel coat finish, these covers offer exceptional weather resistance, structural stability, and low maintenance requirements. Designed to meet the rigorous demands of construction sites, they provide long-term performance in roofing, cladding, and infrastructure applications, outperforming materials prone to rot, corrosion, or warping.

Superior Weather Resistance

The high-quality gel coat surface undergoes extensive xenon arc weathering testing, demonstrating minimal deterioration even after prolonged exposure to sunlight, rain, and temperature fluctuations . Unlike unprotected GRP sheets, which develop fiber protrusions within months, these gel-coated covers remain smooth and intact for decades, with 50% better gloss retention than conventional finishes .

Structural Integrity

Reinforced with a woven glass fiber matrix, the covers achieve a compressive strength of 4309 Pa at 10% deformation, ensuring they withstand heavy foot traffic, equipment placement, and environmental stress . Their lightweight nature (30% lighter than concrete equivalents) simplifies installation, reducing labor costs and structural load on buildings.

Versatility and Safety

Available in custom thicknesses (2mm–10mm) and sizes, the covers accommodate diverse construction needs, from roof hatches to equipment enclosures. The non-conductive GRP material eliminates electric shock risks, while its slip-resistant texture enhances safety in wet conditions.

Commercial and Industrial Roofing

Ideal for covering skylights, ventilation units, and access panels on warehouses, factories, and office buildings, providing watertight protection against leaks.

Infrastructure Projects

Used in bridges, tunnels, and utility stations as protective covers for cables, pipes, and control boxes, resisting corrosion from saltwater and chemicals.

Residential Construction

Suitable for garden sheds, garages, and patio covers, offering a low-maintenance alternative to wood that won’t rot, splinter, or require annual painting.

What is the lifespan of GRP gel coat covers?

When properly installed, they have a service life of 20+ years in outdoor environments, significantly longer than timber (5–10 years) or uncoated metal (10–15 years).

Can the covers withstand extreme temperatures?

Yes, they perform reliably in temperatures ranging from -30°C to 90°C, making them suitable for both cold climates and desert regions.

Are they fire-resistant?

The GRP material is classified as self-extinguishing (UL94 V-0 rating), meeting international fire safety standards for construction materials.

How to clean and maintain the covers?

Routine cleaning with mild detergent and water is sufficient. No repainting or sealing is required, reducing long-term maintenance costs by up to 70% compared to wood.

+86 13913647707 / 13915651436