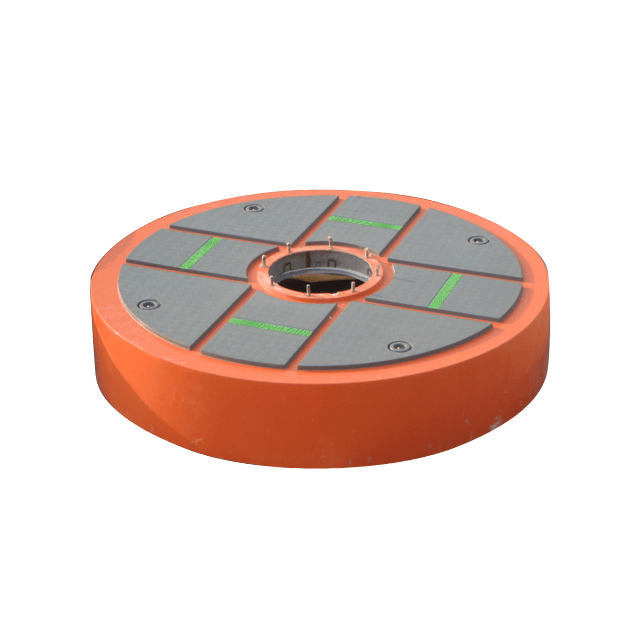

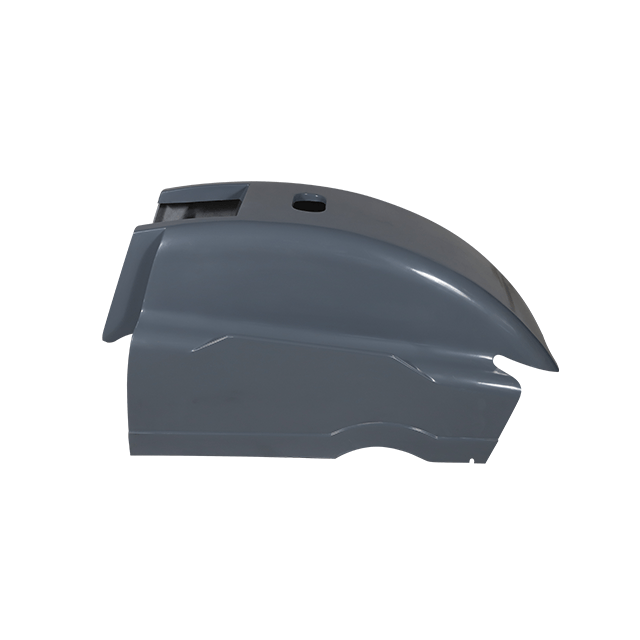

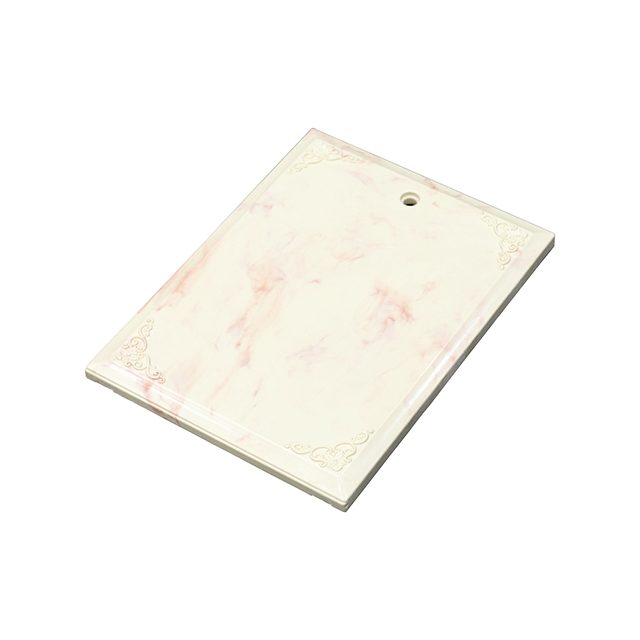

Diversified production process

Professional R&D team, from development pipe design to finished products.

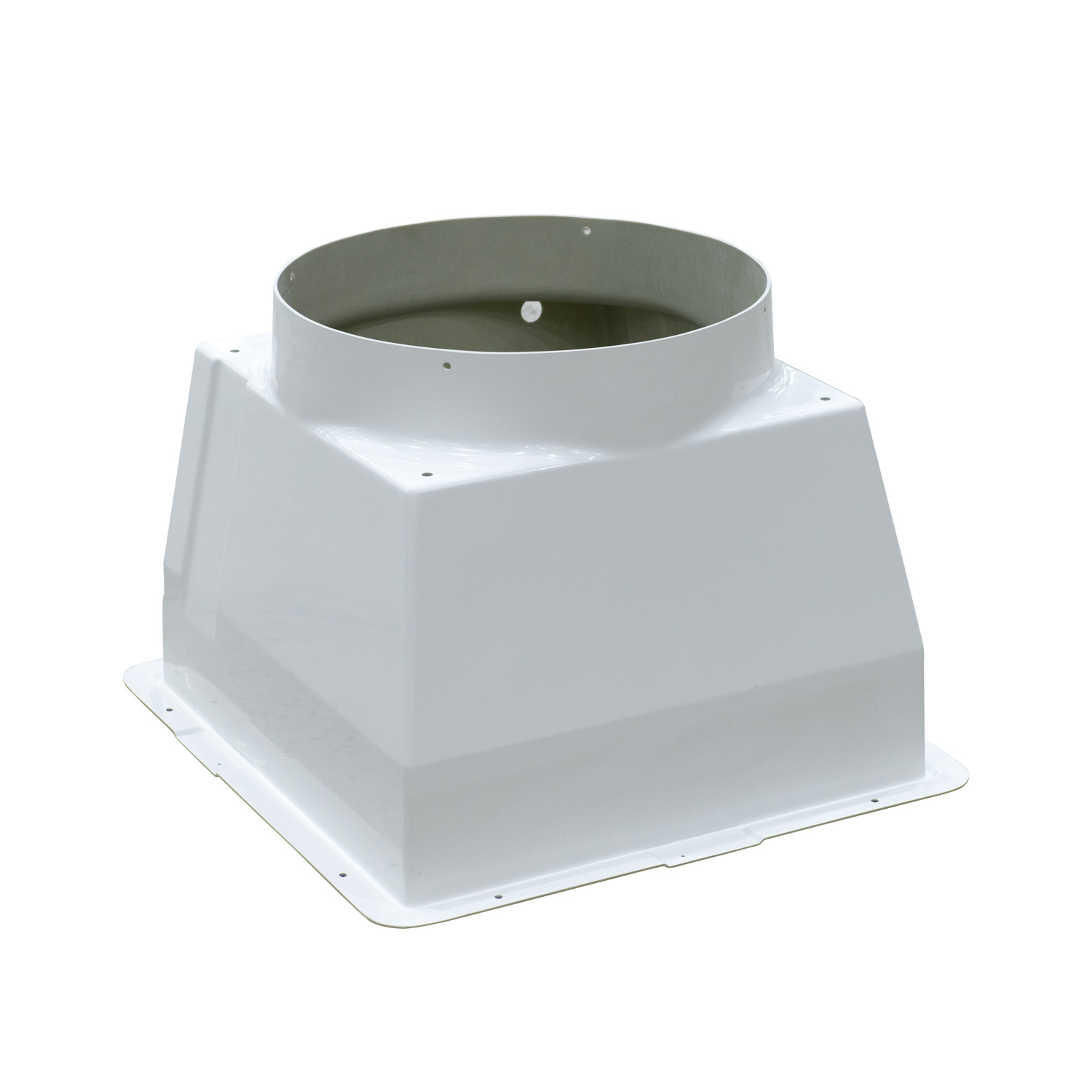

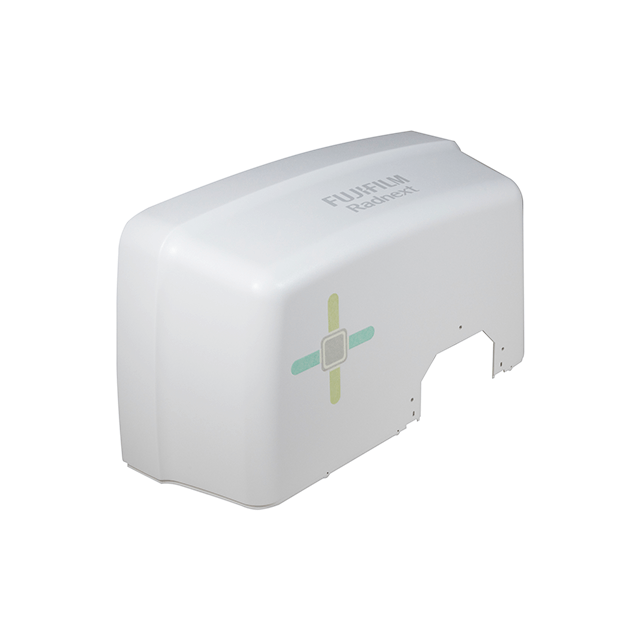

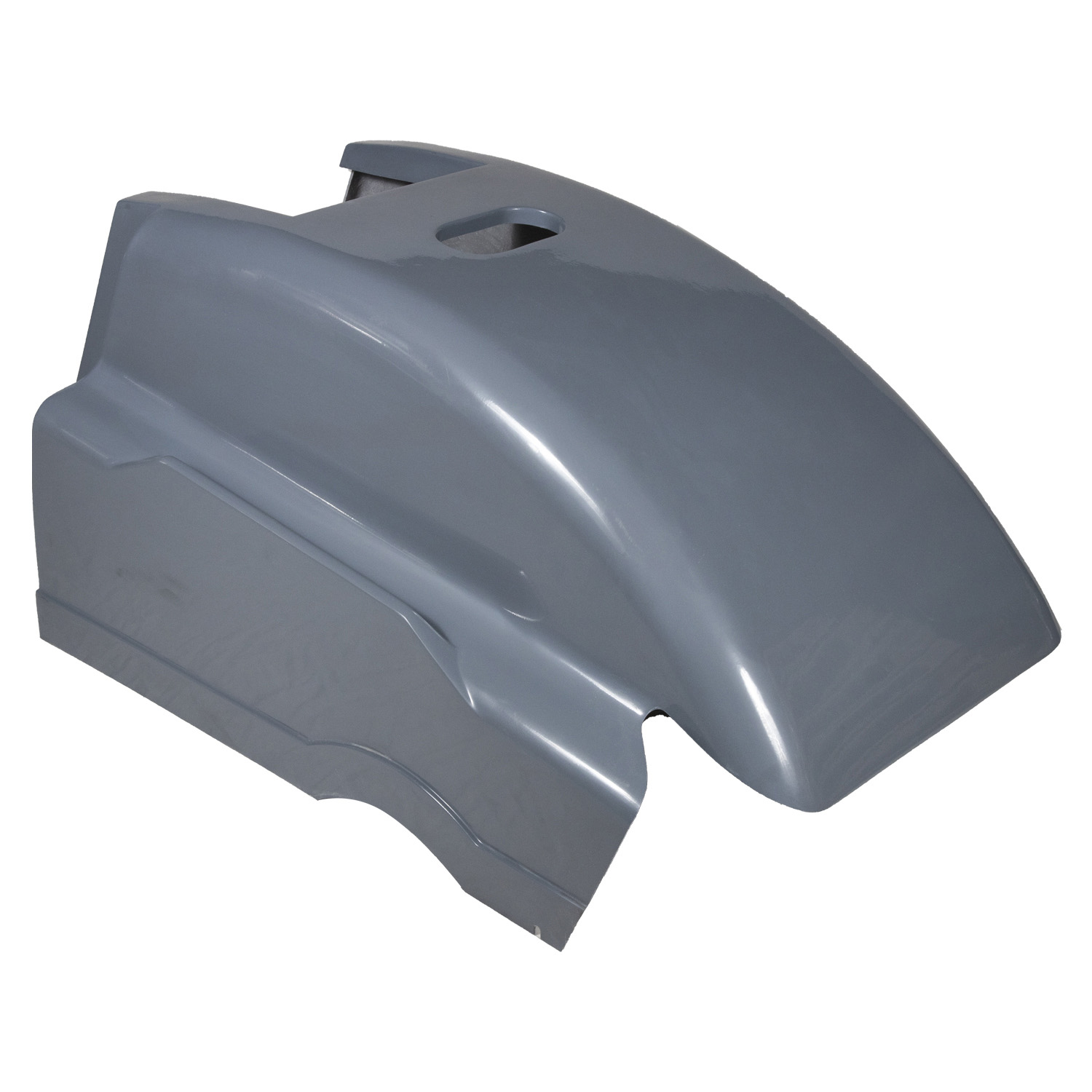

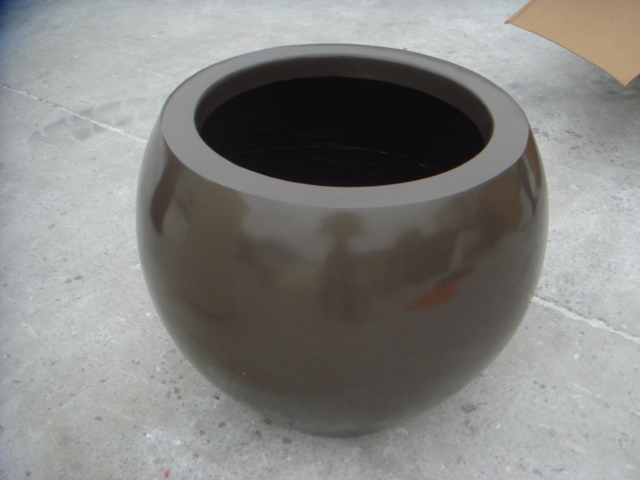

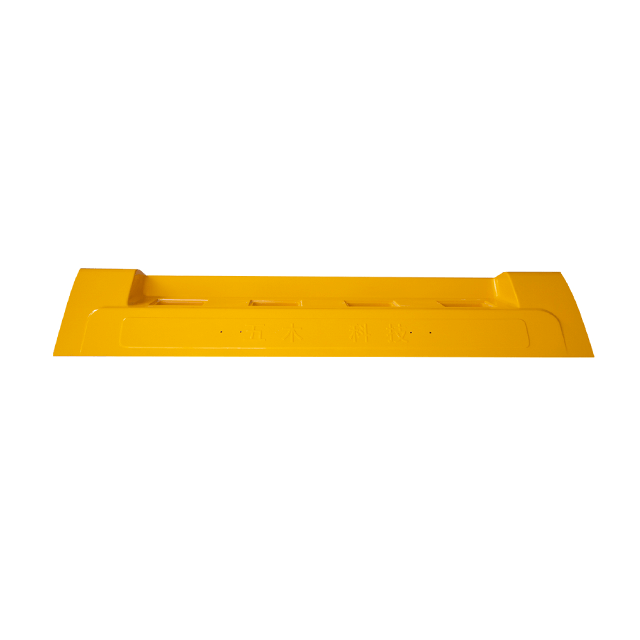

IntroductionFiberglass molding is a popular process for creating strong, lightweight parts. It's used in industries such as automotive, marine, and industrial design. The technique involves layering fiberglass and resin to form durable molds.

IntroductionFiberglass moulds are crucial in industries like automotive, aerospace, and marine. These moulds are crafted from a blend of materials that enhance durability, strength, and performance.

IntroductionCan fiberglass mould really be molded? This versatile material is used across industries for its ability to be shaped into complex, durable forms. From automotive to aerospace, fiberglass mould combines strength with lightweight properties.

IntroductionFiberglass, a versatile and durable material, is used across many industries. Its unique properties—light weight, high strength, and corrosion resistance—make it essential in manufacturing a wide range of products.