Views: 0 Author: Site Editor Publish Time: 2025-08-18 Origin: Site

How long does fiberglass reinforced plastic last? In everyday use, fiberglass reinforced plastic (FRP) delivers many years of service—and often decades—when you match the material and finish to the environment and keep up with simple care. Sun, temperature swings, chemicals, and mechanical stress set the real timeline, and smart design stretches it.

FRP doesn’t rust, shrugs off moisture, and keeps its shape—big reasons it lasts a long time outdoors and in tough facilities.

The right surface layer (gel coat or paint) and consistent processes (closed‑mold RTM or SMC/BMC) protect looks and slow aging.

Edges, holes, and joints decide whether small cracks grow; clean trimming and sealing extend service life.

Color choice and UV‑stable finishes preserve gloss and reduce yellowing under strong sun.

Routine cleaning, fastener checks, and quick touch‑ups are simple ways to add years to FRP panels.

Fiberglass reinforced plastic pairs strong glass fibers with a protective resin. That simple recipe makes it a natural fit for long‑running parts:

No rust: FRP contains no iron, so rain and salt don’t cause the red‑brown corrosion that eats metal over time. This single property raises outdoor FRP durability and keeps maintenance low.

Stable weight and shape: FRP holds stiffness well for its weight. It resists sag and flutter when laid up to the right thickness, so panels stay aligned and look right for years.

Protective outer skin: A gel coat or well‑applied paint forms a dense, smooth barrier that sheds water and blocks sunlight. Less UV reaching the laminate means slower surface aging and better color hold.

Easy cosmetic repair: Chips and scuffs can be sanded and patched, then blended back with paint or gel coat. Those quick repairs keep the premium look while preventing small defects from spreading.

In short, fiberglass reinforced plastic lifespan is strong because the base material resists the common enemies—water and rust—while finishes and sensible design protect the surface and edges.

You can influence how long FRP lasts by making good choices up front. Here are six levers a specifier, designer, or buyer controls.

Resin is the matrix that locks fibers together; the surface is your first defense against weather and sunlight.

Match resin to the environment: General outdoor parts often use polyester resins; when chemicals are present, vinyl ester raises resistance; in demanding mechanical settings, epoxy can help stabilize performance.

Choose a protective skin: Gel coat cures in the mold into a glossy, dense outer layer; paint systems add a flexible film over primer and can be tuned for color and UV. Either way, you’re adding a barrier that slows surface aging.

Keep it UV‑savvy: Light‑colored finishes reflect heat and sun, helping reduce temperature swings. Asking for “UV‑stable” or “UV‑resistant” systems is an easy win for outdoor FRP durability.

Plain‑English note: Gel coat is like a built‑in paint layer that forms as the part is made. Paint is added later. Both can protect the laminate; many programs use gel coat for the base look and paint for color matching.

Strength and stiffness influence how parts resist day‑to‑day loads and fatigue.

Align thickness with use: Large panels usually sit in a practical range of total thickness to avoid warping without adding unnecessary weight. Thicker regions at hinges or mounts help prevent cracks.

Mix fabric forms wisely: Woven fabrics add directional strength; mats help smooth surfaces and distribute loads. Balanced layups keep stiffness uniform so panels age evenly.

Add ribs or cores if needed: Ribs and sandwich cores add bending stiffness without making the whole wall thicker, which reduces weight while holding shape over time.

The point: Predictable stiffness reduces flexing that can cause micro‑cracks and finish damage as years go by.

How you build FRP changes how long it lasts because it changes porosity, wall uniformity, and surface quality.

Hand lay‑up: Flexible and ideal for big shapes or prototypes. Long life is reachable, but results depend on skilled teams and disciplined processes to avoid porosity and thin spots.

Resin transfer molding (RTM): A closed‑mold route that controls thickness, reduces pinholes, and produces clean surfaces. Uniform walls make joints, seals, and edges more reliable long term—useful for FRP panels lifespan in series production.

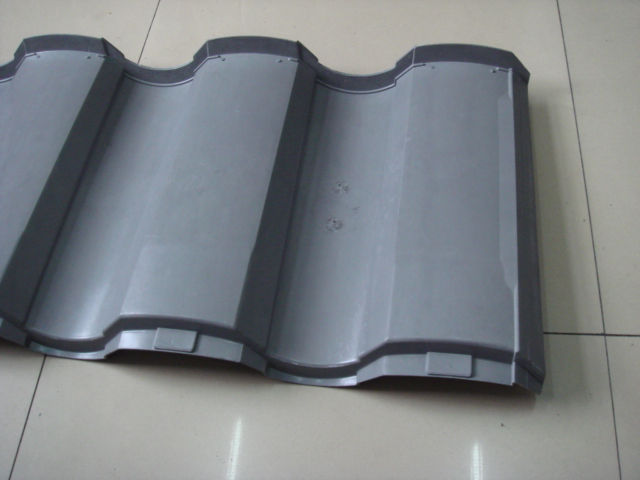

SMC/BMC compression molding: Pre‑compounded sheet (SMC) or bulk (BMC) pressed in heated steel dies. Delivers repeatable parts with integrated ribs and bosses. SMC fiberglass panels often leave the tool with paint‑ready surfaces and consistent thickness that ages predictably.

Consistency is the hidden durability feature: fewer pinholes and more uniform walls mean fewer places for moisture to creep in and fewer thin areas to chalk or crack.

Most long‑term issues start at edges, holes, and joints, not on the smooth middle of a panel.

Finish and seal cut edges: Smooth, sealed edges resist moisture ingress and limit fraying. It’s a small step that pays off over years of exposure.

Place holes with care: Water‑jet cutting leaves crisp edges without the fiber pullout that can form micro‑cracks. Drill bits made for composites also help.

Design gasket lands and drains: Joints that compress a gasket evenly and allow water to drain don’t trap moisture that forces its way into crevices during freeze‑thaw cycles.

Control torque: Overtightening crushes the laminate and deforms seals, which shortens service life around mounts.

If you can keep stress and water out of the edges and joints, you prevent most long‑term headaches.

Sun beats on outdoor parts every day. Color and finish determine how much heat and UV reach the laminate.

Prefer lighter colors for harsh sun: They reflect more heat and reduce thermal cycling that can fatigue finishes.

Add UV‑stability: Modern gels and topcoats contain stabilizers that slow yellowing and chalking. That preserves appearance and reduces the need for refinish.

Smooth matters: Smoother surfaces pick up less dirt and are easier to clean, both of which help the part age better.

Color choice is a simple, low‑cost way to improve fiberglass reinforced plastic durability under strong sunlight.

Long life isn’t “no care”—it’s “low‑stress care.”

Clean surfaces on a schedule: Dirt can hold moisture and hide tiny cracks. Regular washing keeps surfaces cooler and lets you spot issues early.

Touch up chips quickly: Small chips can be sanded and patched, then over‑coated. Skip long delays; water and UV always go for the weak spot.

Check fastener torque: Tight enough for sealing, loose enough to avoid crushing the laminate. This prevents joint fatigue and keeps leaks from starting.

Care routines don’t need to be complex. A short checklist keeps FRP looking new and working right for a very long time.

Longevity isn’t a one‑material race. It depends on your environment, the look you need, your maintenance habits, and how the part is built. Use this comparison as a quick scan before you pick.

| Attribute | FRP (Fiberglass Reinforced Plastic) | PVC (Polyvinyl Chloride) | Steel | Aluminum | Wood |

|---|---|---|---|---|---|

| Outdoor weathering (UV/heat/cold) | Strong with UV‑stable finish; light colors help | Fair; lower heat tolerance; can chalk | Excellent structurally; needs coatings for surface | Excellent; can dull; manages heat well | Variable; needs sealing; UV and moisture drive aging |

| Corrosion and chemicals | No rust; resin‑dependent chemical resistance | Resistant to water; chemical limits apply | Rusts without coatings; chemicals accelerate | No rust; watch galvanic pairs and chemicals | Can rot and swell; chemicals stain |

| Maintenance frequency | Low; clean and touch up as needed | Low to moderate | High in wet/salty areas | Moderate | High for outdoor and wet use |

| Repairability and refinish | Sand/patch/recoat; straightforward | Replace or seal; limited cosmetic refinish | Recoat and treat rust; structural repairs complex | Recoat; dent repair varies | Sand, seal, repaint; can warp/swell |

| Typical service behavior | Many years with the right build; holds shape and look | Many years in mild settings; less stiff | Long life with coatings and care; heavy | Long life; light; premium look | Long life with frequent upkeep; sensitive to exposure |

| Weight and installation | Light to medium; easy handling | Light; easy install | Heavy; strong support needed | Light; precise fasteners | Light to medium; swelling can complicate install |

| Appearance retention | High with gel coat/paint; UV‑stable options | Functional; less “premium” finish | Excellent with paint and prep; chips expose metal | High with anodize/paint; scratches show | Natural look; weathering marks appear |

| Typical applications | Body shells, covers, fiberglass panels, marine enclosures | Liners, cladding, ducts | Frames, tanks with coatings | Enclosures, marine, vehicle panels | Architectural accents, shelters |

How to choose:

Pick FRP when you want a premium surface, curves, and long outdoor FRP durability with low maintenance. It’s a strong aging profile for shells, covers, and public‑facing panels.

Pick PVC for simple liners and claddings in moderate temperatures when cost and quick install matter more than stiffness or gloss.

Pick steel when welded metal seams and very high structural loads define the job, and you’re ready to maintain coatings.

Pick aluminum when you need light, metallic panels and already have a metal assembly ecosystem.

Pick wood for a natural look, knowing that regular sealing and refinishing are part of the plan.

“How long will FRP last outside?” depends on where “outside” is. Think in three bands and apply a few simple rules.

Mild exposure: Temperate climates with modest sun and rain. With a protective finish and basic care, FRP panels deliver many years of stable appearance and shape. Light colors and gentle cleaning extend that.

Moderate exposure: Stronger sun, seasonal heat/cold swings, or regular washing. Ask for UV‑stable gels or paints, seal cut edges, and check fasteners twice a year. Expect long service with minor touch‑ups.

Harsh exposure: Coastal salt, high UV, freeze‑thaw, or chemical splash. Choose a resin tuned for the environment (vinyl ester for harsher chemistry), specify UV‑resistant finishes, seal edges carefully, and schedule inspections. Long service is realistic, but the details matter.

Practical tip: If you’re unsure, build a small set of test panels and run simple exposure tests. That experiment usually costs less than a single round of guess‑and‑check after launch.

Searchers often ask, “What is the life expectancy of a FRP tank?” The honest answer is: it depends on the media inside, the temperature, the pressure, and the maintenance program.

Use this checklist to predict FRP tank life expectancy:

Chemical match: Pick a resin and liner that fit your stored substance (water, brine, acids, alkalis, fuels). Chemical mismatch shortens life quickly; matching extends it.

Temperature and cycling: Elevated temperatures or repeated heat/cold cycles change how fast materials age. Clarify operating ranges before you lock specs.

Pressure and loading: Internal pressure and external loads (supports, wind, impact) affect stress. Overstress speeds crack growth at joints and fittings.

Edges, fittings, and reinforcement: Bonded overlays, inserts, and reinforcement around nozzles and manways distribute loads and reduce crack starters.

Inspection routine: Plan regular checks for surface condition, fittings, and coatings. Early fixes prevent small issues from becoming service life limits.

When you match media and design, and you keep a basic inspection schedule, FRP tanks deliver long service lives with low maintenance. If the environment changes (new chemical, higher temperature), revisit the specification rather than assuming the old plan still applies.

Here’s a simple, how‑to pathway to push fiberglass reinforced plastic lifespan higher without over‑engineering or risking delays.

Define the real environment

List sunlight, temperature range, rain or spray, cleaning routine, and any chemicals. Include how often the part is touched, bumped, or pressure‑washed. This becomes your durability target.

Pick the material and surface

Choose a resin that suits the environment (polyester for general, vinyl ester for harsher chemistry, epoxy in demanding settings). Decide on gel coat, paint, or both, and select light‑fast colors for outdoor FRP durability.

Choose a process that supports consistency

Open‑mold hand lay‑up is flexible for big shapes and short runs, while resin transfer molding (RTM) and SMC/BMC compression molding offer repeatable thickness and surface class—great for FRP panels lifespan in series production.

Engineer the weak spots out

Seal cut edges, design gasket lands and drain paths, and plan holes for clean cutting. Set torque specs that keep seals happy without crushing the laminate.

Validate and adjust before launch

Run sun and spray exposure, thermal cycles, and fit checks. Patch small issues—like a sharper edge or a thin spot—then repeat a short test. You’ll enter production with fewer unknowns and a longer‑lived part.

This map also fits HowTo structured data well if you’re publishing to the web and want to help search engines surface the process steps.

You don’t need exotic labs to prove fiberglass reinforced plastic durability. Simple tests, matched to your environment, correlate well with field life:

Sunlight exposure: Outdoor racks or controlled UV cabinets reveal color hold and chalking trends. Pair with regular photo checks to track gloss.

Thermal cycling: Alternating hot/cold exposures mimic seasonal swings and washdown shocks. Watch joints and mounts, where different materials meet.

Spray and salt: Rain and salt fog simulations show how finishes and edges resist moisture and salt. Look for early signs of wicking along cut edges.

Visual and weight checks: Track surface changes, color shifts, and any weight variations that hint at moisture uptake.

Fastener tests: Re‑torque and leak checks after cycling confirm that sealing lands and inserts age gracefully.

The goal is to build trust in the design, not to invent a number. When tests are honest about the environment, the design choices they guide lead to longer life.

Because FRP resists rust and weather, it finds a home in many long‑life applications:

Urban and public spaces: Covers, enclosures, and decorative fiberglass panels that keep their color and shape even with frequent cleanings.

Transportation covers and shells: Bus, truck, and specialty vehicle shells, body panels, and HVAC housings that handle sun, rain, and washdowns with low upkeep.

Marine and water treatment: Equipment housings and panels that don’t rust in salty spray or damp facilities.

Infrastructure and utilities: Lightweight, strong panels and lids that are simple to install and easy to keep clean.

To see surface options, sizes, and application styles, browse real products and finishes here: fiberglass panels. You’ll find FRP panels built for outdoor duty, with smooth, paint‑ready or gel‑coated surfaces that help them last.

Note: use this link text on your site to guide buyers from research to examples—fiberglass panels—so they can match the look and durability they need to actual parts.

The best design still needs the right factory behind it. Lifespan relies on repeatable processes, clean finishing, and careful trimming. Here’s what matters on the production side:

Process range: When a supplier can do hand lay‑up, resin transfer molding (RTM), and SMC/BMC compression molding, they can match the process to the part rather than forcing compromises that hurt durability.

Equipment that fits: Hydraulic presses across a wide tonnage range support different sizes and ribbed geometries. Stable vacuum and accurate tool alignment in RTM keep thickness consistent. Water‑jet cutting preserves clean edges and holes that stay strong and seal well for years.

Team and QC discipline: Experienced lay‑up teams, stable staffing, and clear inspection stops—from raw fibers and resins to final holes and edges—add up to parts that age gracefully in real environments.

Cross‑industry experience: Lessons from marine spray, public transit washdowns, and chemical plant exposure help prevent known failure modes before the first production run.

A capability snapshot to look for: a plant established in 2000 with a 50,000 m² footprint and around 180 skilled workers; multi‑process coverage (hand lay‑up, RTM, SMC/BMC, fiberglass vacuum forming); hydraulic presses from 315 to 3000 tons; and water‑jet trimming for precise, repeatable edges and holes. A supplier with that footprint can support both prototype agility and steady series production, and that combination supports long service life.

Durability isn’t static. A few current shifts favor even longer service from FRP:

Smarter UV‑stable finishes: Newer gel coats and paints hold color longer and resist micro‑cracking, reducing refinish needs and keeping surfaces glossy.

Integrated joint sealing: Designs that bond and seal in one step reduce field variability, so edges and overlaps stay tight after years of thermal cycles.

Repeatable edges: Water‑jet and CNC processes for trimming have become standard, cutting down on edge defects that shorten life.

Maintenance‑light design: More projects plan cleaning and quick touch‑ups into the spec, setting realistic expectations that preserve appearance and function.

Sustainability focus: Long‑life panels reduce replacements, repainting, and waste—another reason teams lean toward FRP for public‑facing and outdoor gear.

Q1: How long will FRP last outside?

A1: With the right resin and a UV‑aware finish, fiberglass reinforced plastic can serve outdoors for many years—and often much longer. Sun, temperature swings, salt, chemicals, and everyday bumps set the real timeline. Choose finishes and edge sealing to match your climate, and keep a simple cleaning and inspection routine.

Q2: What are the disadvantages of fiberglass reinforced plastic?

A2: FRP needs disciplined manufacturing and finishing. Poor layups create pinholes or thin areas that age faster. Unsealed edges and overtightened fasteners can crack joints. In very high heat, metals may do better. Cosmetic consistency demands good molds, controlled curing, and quality control.

Q3: What is the life expectancy of a FRP tank?

A3: It depends on what’s inside, the temperature, pressure, and care. When resin and liner match the chemical and inspections are regular, tanks run for long service periods. Plan periodic checks for fittings, coatings, and surfaces, and revisit the spec if the media or temperature changes.

Q4: How durable is FRP?

A4: FRP combines a long‑lasting, no‑rust base with a protective outer skin. With gel coat or paint and good edges and joints, it handles weather, washdowns, and everyday knocks for long service across vehicles, infrastructure, and marine equipment.

Q5: Does sunlight cause FRP to yellow or chalk?

A5: Strong sun can fade or yellow unprotected surfaces over time. UV‑stable gel coats and light‑fast paints slow that process noticeably. Light colors help by keeping panels cooler, and routine cleaning preserves the finish.

Q6: Can repairs extend the life of FRP panels?

A6: Yes. Sand and patch chips early, reseal cut edges after any field drilling, and check fastener torque. These small actions prevent moisture ingress and keep the finish intact, extending service life.

Q7: How should I store FRP panels before installation?

A7: Keep panels dry, shaded, and supported. Avoid direct sun and high heat. Protect finished faces from abrasion, and store flat or per supplier guidance to prevent warping and edge damage.

If you need long‑life exterior parts with a clean finish and low maintenance, explore fiberglass panels that are built for outdoor duty. You’ll see options that combine durability with straightforward installation and simple care routines.

From there, outline your environment (sun, temperature, rain, washdowns, chemicals), appearance goals, and volume. A capable supplier can suggest a surface system (gel coat, paint, or both), pick a process that guarantees consistency (RTM or SMC for series panels), and design edges, joints, and holes to age well. They’ll also set up a quick validation loop—sun and spray exposure, thermal cycles, and fit checks—so you go to production confident in fiberglass reinforced plastic lifespan.

So, how long does fiberglass reinforced plastic last? In practical terms, a long time—especially when you pick the right resin and surface for the environment, choose a consistent process, and protect the edges and joints. Outdoors, FRP avoids rust, keeps weight down, and holds a premium look with light, regular care. In tanks and chemical settings, matching the media and maintaining fittings keep service lives strong.

If you’re weighing a switch to FRP or scaling up a program, start by looking at real‑world examples of fiberglass panels designed to go the distance. Then turn your requirements into a quick sample and test plan. With a multi‑process partner, clean trimming, and simple maintenance guidance, your FRP parts will look good, stay solid, and last—year after year.

Explore application‑ready options here: fiberglass panels.

+86 13913647707 / 13915651436