Views: 0 Author: Site Editor Publish Time: 2025-08-08 Origin: Site

Most fiberglass car bodies have 3 or 4 layers. This gives a good mix of strength and lightness. The panels are strong for daily use. They are also light, so the car performs better. Using this many layers keeps the panels about 1/8" to 1/4" thick. This thickness stops warping or cracking. When you add each layer, take out air bubbles. Make sure there are no gaps. Doing this makes the car body smooth and tough. It will last for many years. Jianan also sells fiberglass panels and covers for custom jobs.

Use 3 or 4 layers of fiberglass for most car bodies. This gives a good mix of strength and light weight. - Pick the right fiberglass cloth and resin for each panel. Think about where the panel is and how much stress it gets. - Clean and sand the surface well before you start. This helps the fiberglass stick better. - Put on each layer with care. Remove air bubbles and let each layer dry all the way. This stops weak spots from forming. - After the panels dry, check for soft or thin spots. Fix any damage right away to keep your car safe.

When you work on fiberglass car bodies, you often use 3 or 4 layers. This number gives you panels that are strong but not heavy. Experts say this is a good balance for most cars. Three layers of fiberglass cloth help stop bending and cracking. Four layers make the panel even stronger, which is good for big or stressed spots.

Tip: For a 3’ x 3’ piece, use 3-4 layers of 12oz fiberglass cloth. Overlap the edges by a few inches. This makes the bond better and stops the layers from coming apart.

Always spread resin evenly between each layer. This helps the layers stick and keeps weak spots away. Let each layer dry before you add another one. This stops the layers from peeling apart and keeps your car body strong for a long time.

Here is a simple guide for how many layers to use:

Panel Area | Recommended Layers | Typical Thickness |

|---|---|---|

Side panels | 3-4 | 1/8" - 1/4" |

Hoods/Trunks | 3 | 1/8" |

High-stress zones | 4+ | 1/4" or more |

If you want to make your own project, Jianan has fiberglass car bodies, fiberglass panels, and fiberglass covers. These let you pick the thickness and look you want.

The number of layers in fiberglass panels changes how safe and strong your car is. More layers mean more fiber, which makes the panel tougher and harder to break. Each new layer helps the panel handle more stress and keeps it from getting damaged.

More layers make the panel last longer. The fibers and resin work together to stop cracks.

Lining up the fibers right and using enough resin keeps the panel from peeling or breaking.

If you use special materials like functionalized carbon nanotubes, you can make strong panels with fewer layers. This can make your car lighter and help save gas.

Note: Lighter fiberglass car bodies use less gas and make less pollution. Using the right number of layers and new materials helps you build cars that are better for the planet.

New fiberglass technology lets you use fewer, thinner layers without losing strength. Thermoplastic composites and sandwich panels put the fibers and resin in the best spots. These ways keep your panels strong but also light and efficient.

If you want more choices, look at fiberglass panels and fiberglass covers from Jianan. These help you find what you need for your custom car.

When you choose materials for your car body, you shape how strong and light your panels will be. Most builders use fiberglass cloth, especially E-glass, because it balances strength, weight, and cost. If you pick a heavier cloth, like 12oz fiberglass cloth, you get more strength in each layer. This means you might need fewer layers to reach the right thickness and durability. Lighter cloths need more layers to match the same strength.

You can also combine different materials for better results. For example, using a combo mat with chopped strand and woven rovings gives your panel strength in many directions. This combo soaks up resin well, which helps the layers stick together. You get a smooth finish and a strong panel. Some builders use 12oz fiberglass cloth with a woven roving for high-stress parts. This method works well for car hoods, doors, and even fiberglass panels for custom builds.

Resin choice matters too. Polyester, vinyl ester, and epoxy resins all work with fiberglass. Epoxy resin gives the highest strength and heat resistance. When you use the right resin and cloth together, your car body can handle tough conditions.

Where you put the panel on your car changes how many layers you need. Side panels and doors face bumps and hits, so they need more strength. You might use thicker cloth or add extra layers in these spots. Hoods and trunk lids can use fewer layers if they do not carry much weight.

High-stress areas, like wheel arches or mounting points, need extra care. You can reinforce these spots with more 12oz fiberglass cloth or add a fiberglass cover for protection. Always check the panel after curing. Press gently to feel for weak spots. If you find any, add another layer or patch with more cloth.

Tip: For custom projects, Jianan offers fiberglass car bodies and fiberglass panels. You can pick the right material and thickness for each part of your car.

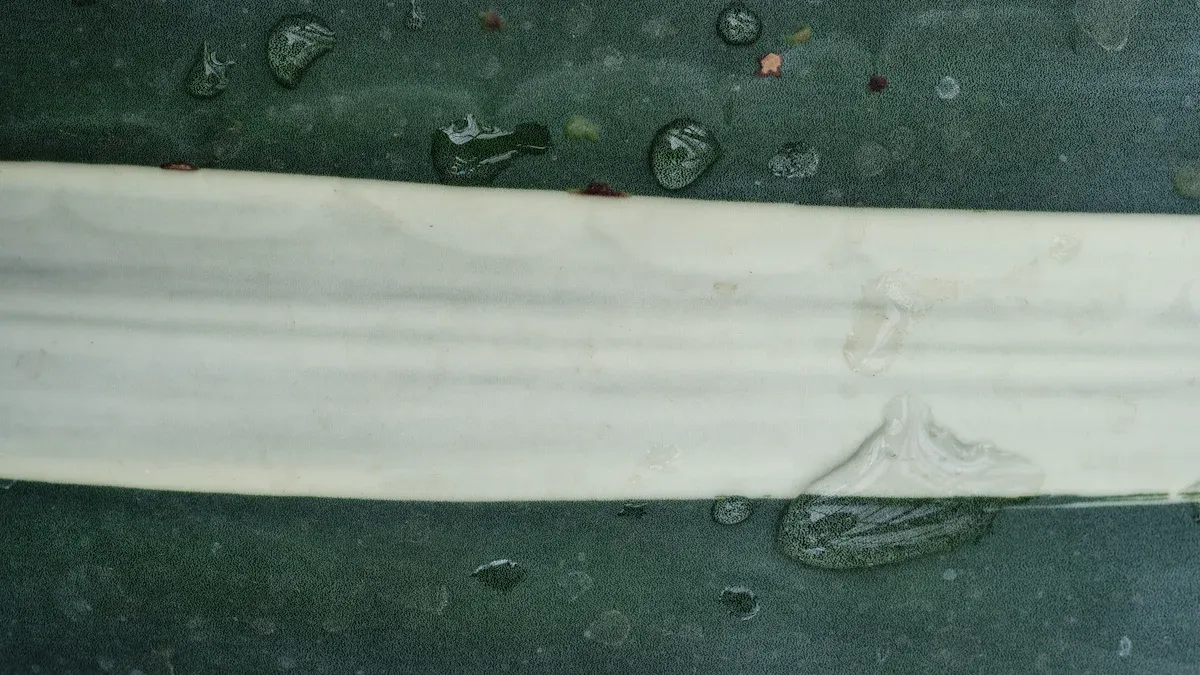

You must get the car body ready before using fiberglass. First, clean the area with acetone to get rid of grease and dust. Sand the surface with 240 grit sandpaper so it feels rough. This helps the fiberglass stick better. Wipe away dust with a tack cloth. Always wear gloves, goggles, and a respirator for safety. Gather your tools like bristle rollers, chip brushes, and squeegees. Make sure you have enough fiberglass mat, resin, and hardener. If you use a mold, put a release agent on it so nothing sticks. Check that your workspace has good airflow.

Cut the fiberglass mat or cloth so it fits the panel. Mix the resin and hardener by following the instructions. Brush a thin layer of resin onto the surface. Put the first layer of fiberglass mat on the wet resin. Use a roller to press down and push out air bubbles. Add more resin if the mat looks dry. Do this for each layer, usually 3 to 4 layers for strength. Let each layer dry until it feels sticky but not wet before adding the next. Overlap the edges of each layer by about an inch. This makes the bond stronger. Do not mix too much resin at once because it can harden fast.

Tip: Always look for air bubbles after each layer. Use the roller to smooth them out before the resin dries.

When the last layer dries, check the panel for weak spots. Press gently on different parts to see if they feel firm. You can use an ultrasonic thickness gauge to check how thick it is. The panel should feel strong and not bend easily. If you find thin or soft spots, add another layer of fiberglass. Sand the surface smooth and trim any rough edges. Good drying and even layers help your car body stay strong. Jianan sells fiberglass car bodies, fiberglass panels, and fiberglass covers to help you get great results.

Common mistakes are leaving air bubbles, using too little resin, or not letting layers dry all the way. These things can make the panel weak and cause trouble later.

You can spot weak or thin areas in fiberglass body panels by using both simple and advanced methods. Start with a visual check. Look for ripples, dents, or uneven spots on the surface. Run your hand over the panel to feel for soft or flexible areas. These signs often mean the panel needs a repair.

For a more detailed inspection, you can use special tools and techniques:

Pulse thermography helps you check large areas quickly and finds defects near the surface.

Lock-in thermography lets you see deeper problems by using frequency changes.

Radiography, such as X-ray or CT scans, shows density changes and helps you find voids or thin spots inside the panel.

Acoustic emission tools listen for sounds that show damage when you put the panel under stress.

Shearography finds hidden defects and areas where the layers do not stick well.

You should also measure the thickness with calipers or micrometers. Guide coats during sanding can help you see small flaws before you finish the panel. Continuous inspection during fabrication keeps your fiberglass body panels strong and safe.

When you find a weak spot or damage, you need to repair it right away. Start by cleaning the area with acetone to remove dirt and grease. Sand the spot to roughen it up and help new material stick. If you need to fix rust holes, begin by cutting out the rust and making sure the area is clean.

Follow these steps to repair the panel:

Assess the damage. Look for cracks, holes, or places where the layers have separated.

Sand away loose fibers and damaged resin. This gives you a solid base for the repair.

Cut fiberglass cloth a bit larger than the damaged area. Mix resin and hardener, then soak the cloth in the mixture.

Apply the cloth to the panel. Use several layers if needed. Make sure each layer sticks well and is fully wet with resin.

Let the repair cure. Sand it smooth to match the rest of the panel.

Use fiberglass filler to patch small holes or cracks. After applying filler, sand it again for a smooth finish.

Finish with primer and paint to protect the repair and match the car’s look.

If you need to fix rust holes in a larger area, cutting out the rust and replacing it with new fiberglass layers works best. Use high-quality fiberglass filler for a strong, lasting result. For complex or safety-critical repairs, or if you feel unsure, you should consult a professional. Auto body shops have the right tools and skills to handle tough jobs and make sure your repair meets safety standards.

Jianan offers fiberglass car bodies, fiberglass panels, and fiberglass covers for your repair needs. You can also find related products like fiberglass planters and fiberglass bins for other projects. Using the right products and following these steps helps you keep your car safe and looking great.

You should use 3 to 4 layers for most fiberglass car bodies. This gives you the right balance of strength and weight for daily driving.

The number of layers depends on your needs, the type of fiberglass cloth, and the area you want to reinforce.

Always check the strength after each step to avoid weak spots.

For best results with custom fiberglass body panels, follow each tip closely and use quality materials like those from Jianan. If you plan a complex project or need extra safety, talk to a professional. Jianan also offers fiberglass panels and fiberglass covers for your next build.

You should repair a fiberglass car body panel if you see cracks, dents, or soft spots. Press on the area to check for weakness. If the panel bends or feels thin, a repair will help keep your car safe and strong.

Yes, you can repair fiberglass panels at home with basic tools and materials. Clean the area, sand it, and apply new fiberglass layers. Always follow safety steps. For large or complex repairs, you may want to ask a professional for help.

You need sandpaper, a roller, resin, fiberglass cloth, and a brush for a repair. Wear gloves and a mask for safety. A fiberglass cover or fiberglass panels from Jianan can make your repair easier and give you better results.

A typical repair takes 24 to 48 hours to cure. Temperature and humidity can change the time. Always wait until the repair feels hard before sanding or painting. This helps your repair last longer and keeps your car body strong.

You should repair small cracks or holes. If the damage is large or affects safety, replace the panel. Jianan offers fiberglass panels and fiberglass car bodies for easy replacement. Always check if a repair will keep your car safe before you decide.

+86 13913647707 / 13915651436