FRP (Fiberglass Reinforced Plastic) panels are advanced composite materials made from a combination of fiberglass and resin, typically polyester or epoxy. Known for their exceptional strength, durability, and resistance to environmental factors, FRP panels are widely used in various applications, including construction, transportation, and marine settings. Their lightweight nature and low maintenance requirements make them an ideal choice for industries seeking reliable and cost-effective solutions. This article delves into the composition, manufacturing processes, types, and diverse applications of FRP panels, highlighting their unique benefits and advantages.

FRP panels mainly consist of two key materials: fiberglass and resin. Fiberglass is made from ultra-fine glass fibers, typically 4 to 30 microns in diameter. These fibers provide strength and flexibility. The resin, usually polyester or epoxy, acts as a binder, holding the fibers together and forming a solid matrix. Sometimes additives like fire retardants or UV inhibitors are included to enhance performance.

Fiberglass can come in different forms, such as woven cloth, chopped strands, or continuous filaments. The choice depends on the required strength and application. Polyester resin is popular due to its good mechanical properties and cost-effectiveness, while epoxy resin offers superior durability and chemical resistance.

The manufacturing of FRP panels starts by layering fiberglass sheets or mats. The resin is applied over these layers to impregnate the fibers thoroughly. This can be done by hand lay-up, spray-up, or automated processes like pultrusion.

Once the resin saturates the fiberglass, the panel is shaped and cured. Curing involves heating the material to harden the resin, locking the fibers in place. This process ensures the panel gains its strength, rigidity, and durability. Additional coatings may be applied to improve surface finish or add protective features.

There are two main manufacturing methods based on fiber type:

● Continuous Filament Process: Uses long, continuous glass fibers woven into cloth or mats. This method produces panels with higher strength and better impact resistance. It is common in structural applications where durability is critical.

● Short Fiber Process: Employs chopped or short glass fibers mixed randomly in the resin. This process is faster and more cost-effective but results in panels with slightly lower mechanical properties. It suits applications where moderate strength and faster production are priorities.

Both methods involve layering fiberglass and resin, but the fiber form affects the panel’s final performance and cost.

Choosing between continuous filament and short fiber FRP panels depends on your project’s strength requirements and budget—continuous filament offers superior strength, while short fiber panels provide cost savings and faster production.

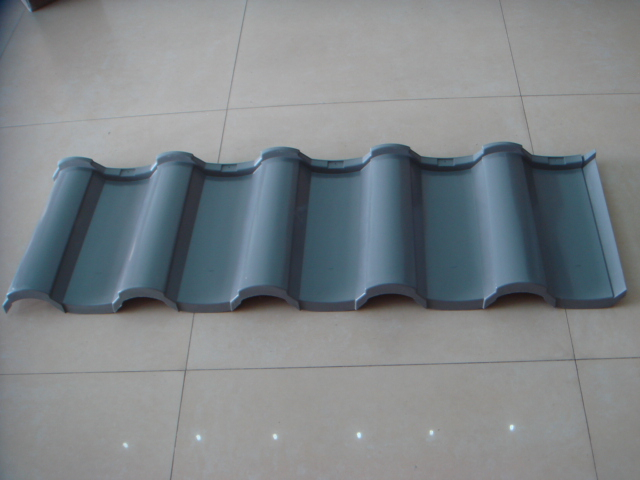

FRP panels come in various types, each designed to meet specific needs. The main types include:

● Flat FRP Panels: These are smooth, flat sheets commonly used for wall coverings, partitions, and ceilings. They offer a clean look and are easy to install.

● Textured FRP Panels: These panels have patterns or embossed surfaces to enhance aesthetics or provide slip resistance. They are popular in commercial kitchens, hospitals, and public restrooms.

● Sandwich Panels: These combine FRP skins with a core material like foam or honeycomb, offering excellent insulation and structural strength. They are widely used in refrigerated trucks, cold rooms, and building panels.

● Fire-Retardant FRP Panels: Specially formulated to resist fire, these panels are essential in environments where fire safety is critical, such as industrial plants and public buildings.

● Decorative FRP Panels: Available in various colors and finishes, these panels serve both functional and aesthetic purposes, often used in interior design and architectural applications.

Fiberglass tape and cloth are versatile forms of fiberglass used alongside FRP panels to enhance strength and durability. Their main applications include:

● Fiberglass Tape: Used for reinforcing joints, seams, and cracks. It helps prevent structural failure and improves impact resistance. It’s common in boat building, automotive repair, and construction.

● Fiberglass Cloth: Woven fiberglass fabric used as a reinforcement layer in composite manufacturing. It provides excellent tensile strength and flexibility. Common in aerospace, marine, and automotive industries for making lightweight, strong parts.

● Fire Curtains and Heat Shields: Fiberglass cloth’s heat resistance makes it suitable for protective barriers in industrial settings.

● Sealing and Insulation: Fiberglass tape and cloth help seal gaps and insulate surfaces against heat and moisture.

While traditional FRP panels mainly come in white or black, modern manufacturing techniques allow a broad range of color and texture options to suit design needs:

● Color Options: FRP panels can be pigmented during production to produce vibrant colors, including shades of blue, green, red, and custom hues. This allows matching with brand colors or interior themes.

● Texture Choices: Panels can be smooth, matte, glossy, or embossed with patterns like wood grain, leather, or geometric designs. Textured surfaces improve grip and hide scratches or dirt.

● Custom Finishes: Some manufacturers offer coatings that enhance UV resistance, gloss, and durability, making panels suitable for outdoor use without fading or degradation.

These variations make FRP panels adaptable to many environments, from industrial spaces to stylish commercial interiors.

When selecting FRP panels, consider the specific application environment and aesthetic requirements—textured or colored panels can enhance both functionality and design appeal.

FRP panels and Aluminum Composite Panels (ACP) often compete in construction and industrial applications. However, FRP panels offer superior chemical resistance. Unlike ACP, which can corrode or degrade when exposed to acids, alkalis, or chlorine-based chemicals, FRP withstands harsh environments without rusting or weakening. This makes FRP ideal for use in chemical plants, marine settings, and outdoor applications where moisture and corrosive agents are common.

In terms of strength, FRP panels excel in fatigue resistance and bending strength. ACPs, while strong, tend to deform or fatigue under continuous stress or high loads. Additionally, FRP panels have lower thermal conductivity than ACP, helping maintain temperature stability in insulated structures. This makes FRP a better choice for refrigerated trucks and cold storage facilities.

Compared to carbon fiber, FRP panels are more cost-effective while still offering excellent strength and durability. Carbon fiber is lighter and stronger but comes at a significantly higher price, limiting its use to specialized applications like aerospace or high-performance sports equipment.

Steel is known for its strength and durability, but it is heavy and prone to corrosion unless properly coated or maintained. FRP panels provide a lightweight alternative that resists rust and requires less upkeep.

Acrylic panels offer good clarity and weather resistance but lack the mechanical strength of FRP. Acrylic is brittle and can crack under impact, whereas FRP panels absorb shocks and resist damage better.

FRP panels thrive in environments where moisture, chemicals, and temperature fluctuations challenge other materials. Their corrosion resistance makes them ideal for marine vessels, chemical processing plants, and outdoor architectural applications. FRP panels also resist UV radiation and do not fade or degrade easily, maintaining appearance and performance over time.

In humid or wet environments, FRP panels prevent mold and mildew growth due to their non-porous surface. Their lightweight nature reduces structural load, beneficial in vehicle manufacturing and modular construction.

Moreover, FRP panels combine strength and flexibility, allowing them to withstand impact and bending without cracking. This durability reduces maintenance costs and extends service life.

When choosing between FRP and other materials, consider the environment’s chemical exposure, moisture levels, and structural demands—FRP often offers the best balance of durability, resistance, and cost-effectiveness.

FRP panels play a crucial role in the manufacturing of recreational vehicles (RVs) and enclosed trailers. Their lightweight nature helps improve fuel efficiency and drivability by reducing overall vehicle weight. At the same time, FRP provides excellent durability to protect internal structures from wear and tear during travel. Many RV manufacturers use fiberglass foam panels and plywood panels reinforced with FRP to combine strength and rigidity. This combination ensures the vehicle withstands vibrations and impacts on the road, enhancing longevity.

Enclosed car trailers also benefit from FRP panels. They provide a tough outer shell that resists dents, corrosion, and weather damage. This protection is vital for safely transporting vehicles or goods, especially in varying climates and terrains.

FRP panels combined with foam cores create effective acoustic and thermal insulation solutions. For example, FRP foam acoustic panels are designed to reduce noise pollution by absorbing sound waves. These panels improve comfort levels in homes, offices, or industrial settings by minimizing echo and ambient noise.

Thermal insulation is another important application. FRP XPS (extruded polystyrene) and PU (polyurethane) foam sandwich panels are widely used in refrigerated trucks, cold rooms, and insulated buildings. The panels’ low thermal conductivity helps maintain stable interior temperatures, reducing energy consumption. They prevent heat transfer from outside, keeping refrigerated goods fresh or indoor environments comfortable.

These panels are also used in roofs, walls, and floors where thermal insulation is critical. Their resistance to moisture and chemicals ensures long-term performance without degradation.

In marine environments, FRP panels are highly valued due to their resistance to seawater corrosion and abrasion. They are used to build ship cabins, decks, and hull reinforcements. FRP’s lightweight yet strong properties help improve fuel efficiency and vessel stability. The panels also provide a comfortable living environment by resisting mold and mildew growth common in humid marine settings.

For exterior wall finishes, FRP panels offer excellent protection against weather elements such as rain, UV radiation, and temperature extremes. Manufacturers often apply UV-resistant coatings to prevent fading and surface damage. These panels can be customized with various colors and textures to fit architectural styles, making them popular in commercial and residential buildings.

Their durability reduces maintenance costs and extends the lifespan of exterior surfaces exposed to harsh environments.

When choosing FRP panels for vehicles or buildings, consider their specific environmental exposure—marine and exterior wall uses require UV and corrosion-resistant coatings to ensure long-term durability.

FRP panels are known for their impressive strength. They combine fiberglass’s tensile strength and resin’s rigidity to create a material that resists bending, cracking, and impact damage. This makes them ideal for applications where mechanical stress is common. Unlike many traditional materials, FRP panels maintain their structural integrity even after prolonged use. They do not warp or deform easily, which means they provide reliable performance over time.

The durability of FRP panels also means they withstand heavy loads and repeated impacts without losing shape. This quality is especially valuable in transportation, construction, and industrial settings where materials face constant wear and tear.

One of the standout features of FRP panels is their resistance to harsh environmental conditions. They are highly resistant to moisture, preventing issues like mold, mildew, and rot that affect wood or metal panels. This makes FRP panels perfect for humid or wet environments, such as marine applications or exterior walls.

Moreover, FRP panels resist chemicals, including acids, alkalis, and solvents. This chemical resistance ensures they perform well in factories, laboratories, or areas exposed to corrosive substances. They also withstand UV radiation, reducing fading or surface degradation when used outdoors.

FRP panels do not rust or corrode like metals, which lowers maintenance requirements and extends their service life. Their smooth, non-porous surface also helps prevent dirt buildup and makes cleaning easier.

FRP panels offer excellent value for money. Their long service life reduces the need for frequent replacements, saving costs over time. Because they resist damage and environmental wear, maintenance expenses are lower compared to other materials like steel or wood.

Installation is straightforward and quick, which cuts down labor costs. The lightweight nature of FRP panels also reduces transportation and handling expenses. Additionally, their resistance to chemicals and moisture means fewer repairs and less downtime.

Cleaning FRP panels is simple; a quick wash with mild detergent keeps them looking new. Their scratch-resistant surface helps maintain aesthetics and functionality without special treatments.

When choosing panels for a project, consider FRP for its unbeatable combination of strength, environmental resistance, and low maintenance costs to maximize long-term savings and reliability.

Cutting FRP panels requires the right tools and careful handling. Use a fine-toothed saw, such as a circular saw with a carbide blade or a jigsaw, to ensure clean cuts without chipping. Always wear protective gear like gloves and a mask, since fiberglass dust can irritate skin and lungs.

When installing, clean the surface thoroughly to remove dust and grease. FRP panels can be attached using adhesives, mechanical fasteners, or a combination of both. For wall applications, construction adhesive works well, while screws with washers provide secure fastening for structural uses. Make sure to leave a small gap between panels to allow for expansion and contraction due to temperature changes.

Sealing the joints with silicone or specialized FRP sealants prevents moisture infiltration and maintains panel integrity. Avoid over-tightening screws to prevent cracking. Properly installed FRP panels offer a smooth, durable surface that resists impacts and moisture.

FRP panels are designed for long service life, often lasting 20 years or more when maintained properly. Their resistance to corrosion, moisture, and chemicals means they rarely degrade like wood or metal.

To extend lifespan, clean panels regularly using mild detergent and water. Avoid harsh abrasives or solvents that might damage the surface. Inspect panels periodically for cracks or loose fasteners, especially in high-traffic or exposed areas. Promptly repair any damage using fiberglass repair kits or professional services.

Avoid prolonged exposure to extreme UV without protective coatings, as this may cause slight surface degradation over decades. However, many FRP panels come with UV inhibitors to minimize this risk.

FRP panels have both advantages and challenges regarding environmental impact. Their durability means fewer replacements and less waste over time, which reduces resource consumption. Their lightweight nature lowers transportation emissions compared to heavier materials like steel or concrete.

However, FRP production involves synthetic resins and fiberglass, which rely on non-renewable resources. Recycling options remain limited because separating fiberglass from resin is difficult. Some manufacturers are developing bio-based resins and recyclable composites to improve sustainability.

Proper disposal or repurposing of FRP panels at end-of-life is important to minimize landfill waste. Using FRP in applications that extend product life and reduce maintenance helps balance environmental concerns.

Use carbide-tipped saw blades and seal panel joints carefully during installation to ensure clean cuts and long-lasting, moisture-resistant FRP panel assemblies.

FRP panels, made from fiberglass and resin, offer strength, durability, and resistance to environmental factors. They excel in various applications, including vehicles, insulation, and marine settings, due to their lightweight and corrosion-resistant properties. As demand grows, future trends may include more sustainable production methods. About Jianan - Your Trusted Fiberglass Manufacturer provides high-quality FRP panels that deliver exceptional value through their unique benefits, such as reduced maintenance and long-lasting performance, making them an ideal choice for diverse industries.

A: FRP panels are composed of fiberglass and resin, typically polyester or epoxy, providing strength and durability.

A: FRP panels are used for wall coverings, ceilings, and insulation in construction due to their strength and moisture resistance.

A: FRP panels offer superior chemical resistance and lower thermal conductivity compared to aluminum composite panels.

A: FRP panels are cost-effective due to their durability, low maintenance, and ease of installation, reducing long-term expenses.

+86 13913647707 / 13915651436