Views: 0 Author: Site Editor Publish Time: 2025-07-14 Origin: Site

When selecting materials for construction, roofing, insulation, and other applications, the choice between fiberglasspanels and metal sheets often arises. Both materials are durable, versatile, and widely used across various industries, but each has unique properties that make it better suited for specific tasks. In this article, we will compare fiberglass panels and metal sheets based on key factors like strength, durability, cost, maintenance, applications, and environmental impact. By the end, you'll be able to decide which material is best suited for your project.

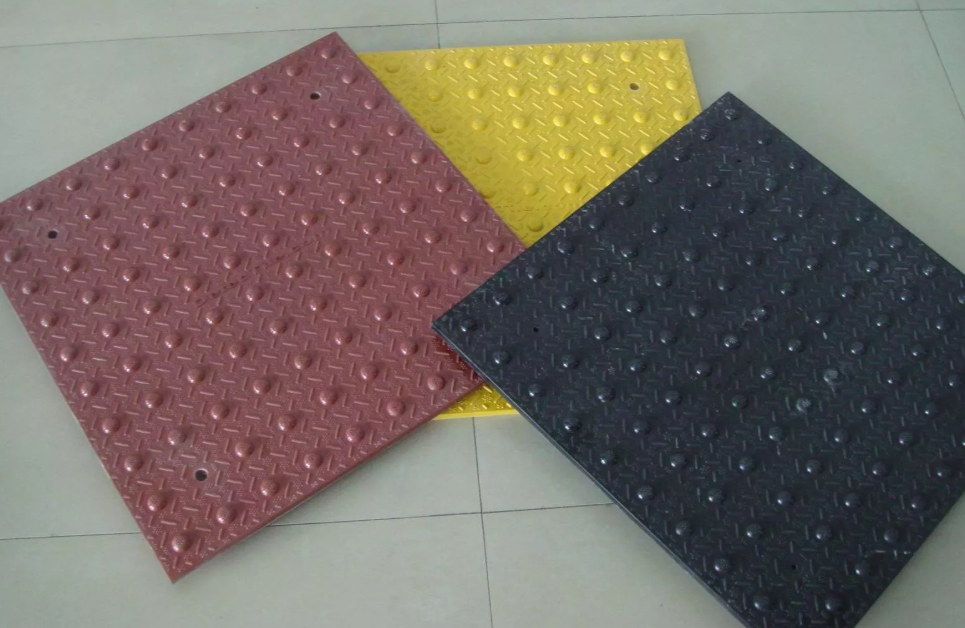

Fiberglass panels are created by weaving glass fibers and bonding them with a resin. This results in a lightweight yet strong material that is often used in a variety of industries. It is popular for its resistance to weather, UV rays, and corrosion. Fiberglass is most commonly used in applications like roofing, insulation, and decorative designs. It can be manufactured in many different forms, including solid, translucent, and patterned panels.

Key Features:

Lightweight yet durable

UV and weather-resistant

Flame-retardant

Customizable in color and design

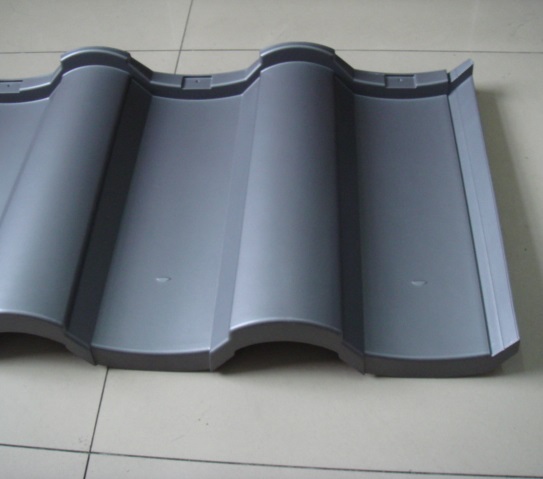

Metal sheets are thin, flat pieces of metal made from materials such as steel, aluminum, or galvanized iron. They are commonly used for their strength, heat resistance, and ability to withstand physical wear and tear. Metal sheets are used in industrial, commercial, and residential applications for their superior strength and versatility.

Key Features:

High tensile strength and impact resistance

Corrosion-prone unless treated with protective coatings

Heat-resistant and can be used in fire-prone areas

Available in various metals like steel, aluminum, and copper

Fiberglass Panels:

Fiberglass panels are strong, but they lack the level of impact resistance that metal sheets offer. They are more likely to crack or shatter under heavy force, especially in colder temperatures.

Fiberglass excels in resisting weathering, UV degradation, and corrosion, making it ideal for long-term outdoor use. However, it is generally not as resistant to physical impact as metal sheets.

Metal Sheets:

Metal sheets, especially steel and aluminum, offer superior strength and tensile resistance. They are much more resistant to physical impacts, making them a better option in applications where durability and structural integrity are crucial.

Metal is prone to rusting and corrosion, especially in moist or coastal environments, unless coated with galvanized or painted finishes.

Fiberglass Panels:

Fiberglass panels are lightweight, which makes them easier to transport and install. This reduces labor costs and makes fiberglass a preferred material for large projects where installation time and costs are important.

Their lightweight nature also means that they typically require less support in terms of framing.

Metal Sheets:

Metal sheets are significantly heavier than fiberglass panels, which can increase transportation and installation costs. They may require stronger framing and support structures, adding to the overall cost of installation.

Fiberglass Panels:

Initial Costs: Fiberglass panels are generally more affordable in terms of material costs, making them an attractive option for budget-conscious projects. They also have lower installation costs due to their lightweight nature.

Long-term Costs: Fiberglass panels tend to have lower maintenance costs because they are resistant to rust, corrosion, and UV damage. With minimal upkeep, they can last a long time without needing repairs.

Metal Sheets:

Initial Costs: Metal sheets, especially those made from high-quality metals such as steel or aluminum, tend to be more expensive. The initial costs can be significant, especially for large projects.

Long-term Costs: While metal sheets are durable, they require maintenance in the form of rust prevention, occasional painting, or other protective treatments. This can increase long-term costs, particularly in environments exposed to moisture.

Fiberglass Panels:

Fiberglass is virtually maintenance-free. It does not rust, corrode, or degrade under UV exposure, making it ideal for long-term use in both residential and commercial applications.

With proper care, fiberglass panels can last anywhere from 10 to 20 years without needing significant repairs.

Metal Sheets:

Metal sheets require more maintenance than fiberglass. Regular inspection for rust and corrosion is necessary, especially in coastal or humid climates. Even galvanized metal can degrade over time if not properly maintained.

Metal sheets can last several decades if well-maintained, but their longevity can be impacted by exposure to moisture and air if left untreated.

Fiberglass Panels:

Fiberglass is often used for skylights, patio covers, and roofing domes due to its ability to allow light to pass through while offering UV protection. It is ideal for residential roofing, especially in areas where light transmission and insulation are important.

Fiberglass is popular in greenhouses and outdoor canopies due to its weather-resistant properties.

Metal Sheets:

Metal roofing is common in industrial, commercial, and agricultural settings, where the primary concern is structural strength and fire resistance.

Metal sheets are widely used for warehouse roofing, barns, and large-scale commercial buildings due to their durability and heat resistance.

Fiberglass Panels:

Fiberglass is often used for insulation in both residential and industrial settings. It provides excellent thermal and sound insulation, making it ideal for use in walls, ceilings, and floors.

In commercial spaces,fiberglass panels are used for temporary partitions or walls that need to be both durable and easy to install or move.

Metal Sheets:

Metal sheets are not generally used for insulation purposes, as they do not provide adequate thermal resistance. However, they are sometimes used for soundproofing in industrial applications where noise control is important.

Fiberglass Panels:

Widely used in the automotive and marine industries for body panels, boat hulls, and RV construction due to its lightweight nature and resistance to corrosion. Fiberglass is an excellent choice for applications that require both strength and lightness.

Metal Sheets:

Metal sheets are commonly used for vehicle body panels, truck beds, and boat hulls. Metals like aluminum and stainless steel are used for their structural strength, resistance to wear, and durability.

Fiberglass Panels:

Fiberglass is not easily recyclable, which poses an environmental challenge. While fiberglass has a long lifespan, it cannot be reused in the same way that metal can, leading to landfill waste if not properly disposed of.

Metal Sheets:

Metal sheets, especially steel and aluminum, are highly recyclable. Scrap metal can be melted down and reused without losing any strength or quality. This makes metal a more environmentally sustainable choice compared to fiberglass.

Fiberglass Panels:

The production of fiberglass requires the use of energy-intensive processes, including heating and curing the glass fibers. However, the lightweight nature of fiberglass means it has a smaller carbon footprint during transportation.

Metal Sheets:

The production of metal sheets is highly energy-intensive due to mining, refining, and manufacturing processes. However, recycled metals reduce the environmental impact and energy consumption associated with new metal production.

Cost: If you have a limited budget, fiberglass panels are more affordable both in terms of initial investment and long-term maintenance.

Strength Requirements: If you need a material that can withstand heavy impacts or extreme conditions, metal sheets offer superior strength.

Environmental Concerns: If sustainability is a priority, metal sheets are more environmentally friendly due to their recyclability.

Maintenance: If you want a material that requires minimal upkeep, fiberglass is the clear choice.

In conclusion, whether fiberglass panels or metal sheets are better for your project depends on your specific needs. Fiberglass panels are ideal for projects where low maintenance, cost-efficiency, and moderate durability are required, while metal sheets are better suited for heavy-duty applications where strength, impact resistance, and fireproofing are crucial. Both materials have their advantages, and understanding the differences will help you make an informed decision for your next construction, renovation, or industrial project.

A:While fiberglass panels are strong, metal sheets are generally stronger in terms of tensile strength and impact resistance. Fiberglass excels in weather resistance and corrosion resistance, but metal is better for heavy-duty applications.

A:Yes, metal sheets are widely used for roofing, especially in commercial and industrial settings. However, fiberglass panels are often preferred for residential roofs, skylights, and areas where light diffusion is required.

A:Fiberglass panels generally require less maintenance than metal sheets because they do not rust or corrode. Metal sheets need periodic maintenance to prevent rust and deterioration, particularly in harsh environments.

A:Fiberglass panels are much better for insulation due to their thermal resistance and ability to help maintain energy efficiency, making them an excellent choice for walls, roofs, and floors.

+86 13913647707 / 13915651436