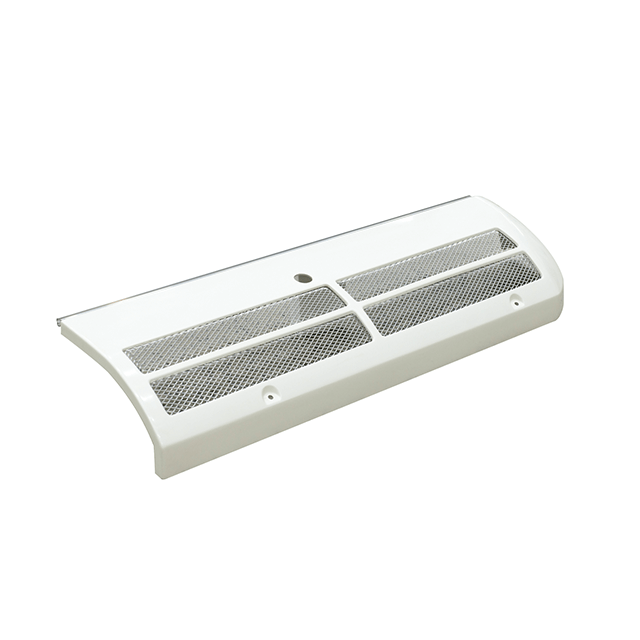

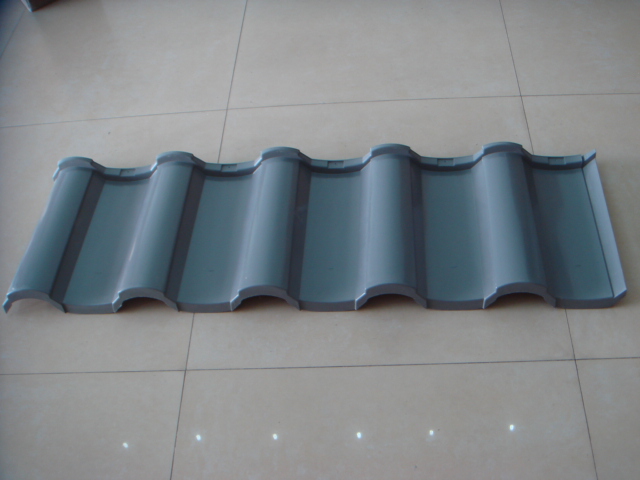

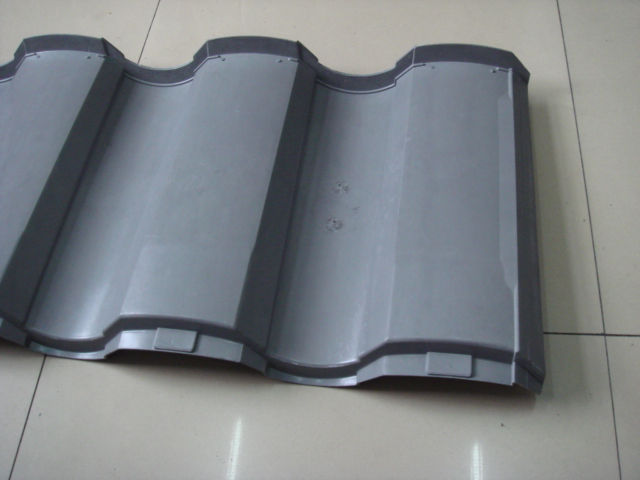

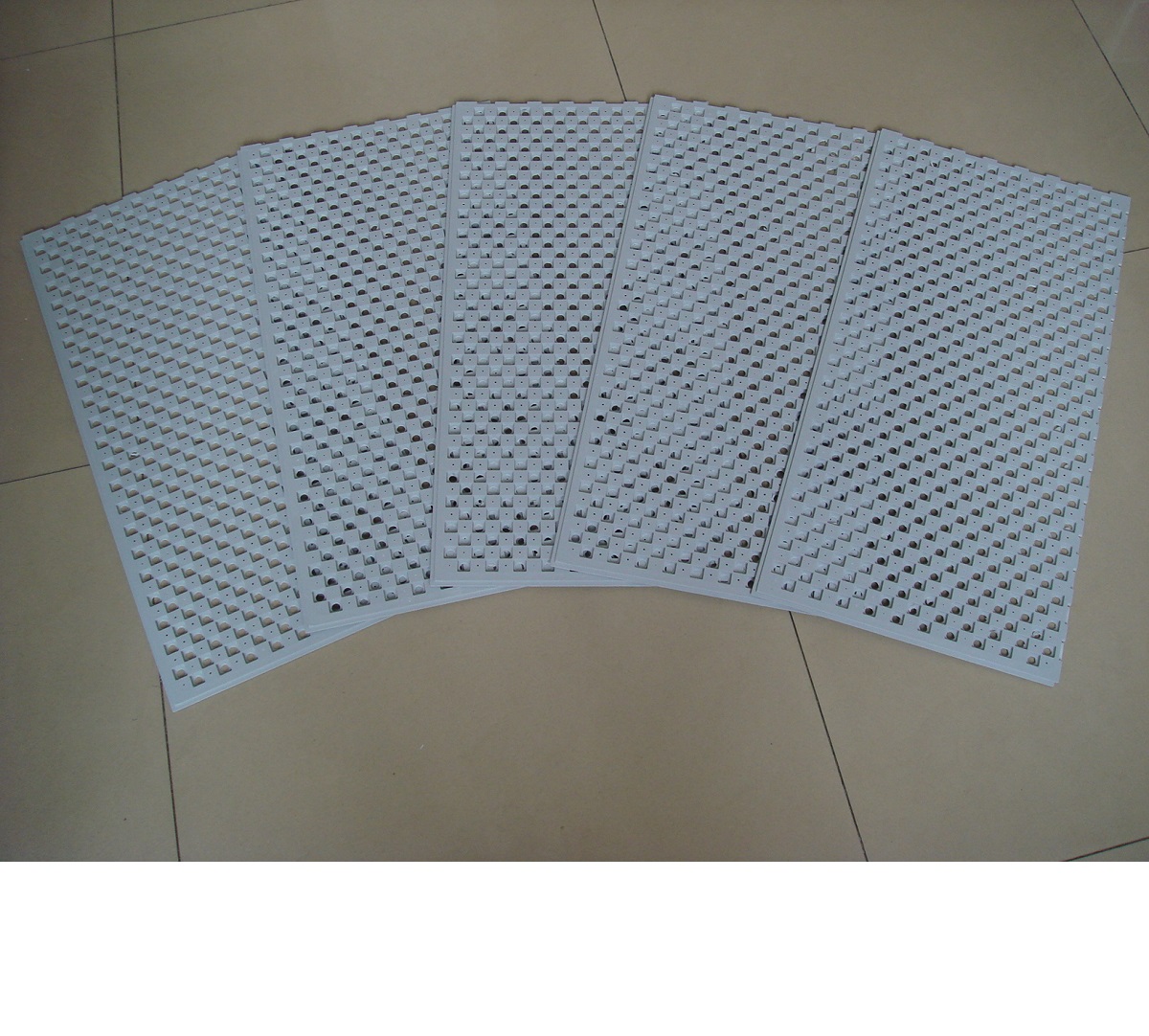

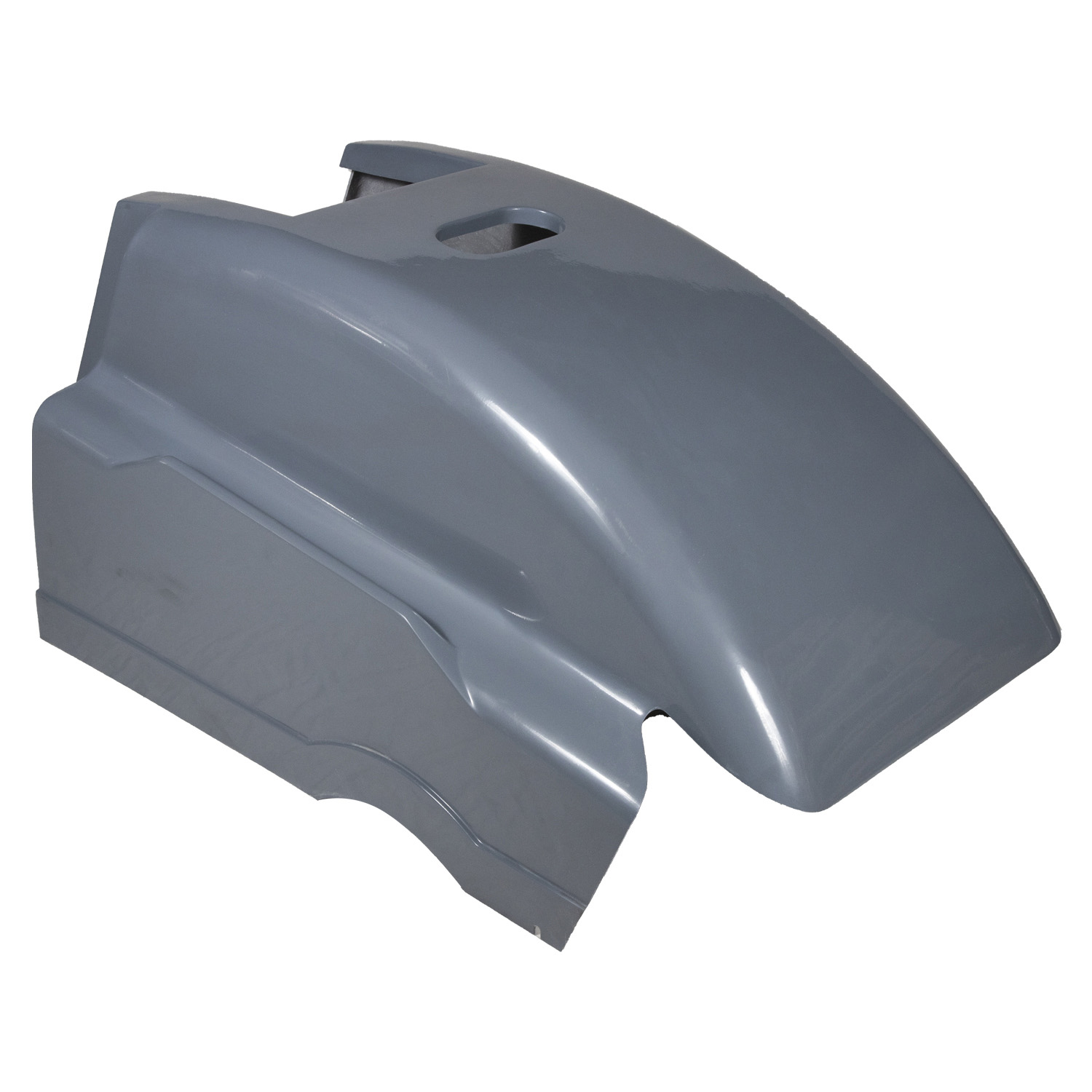

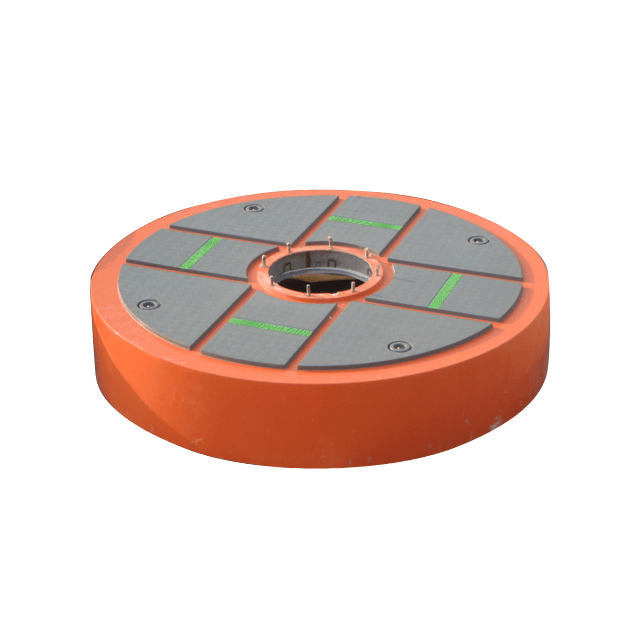

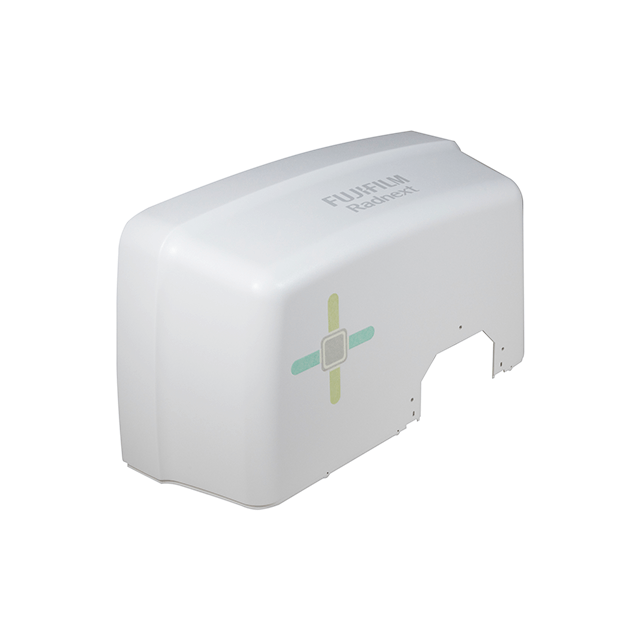

Diversified production process

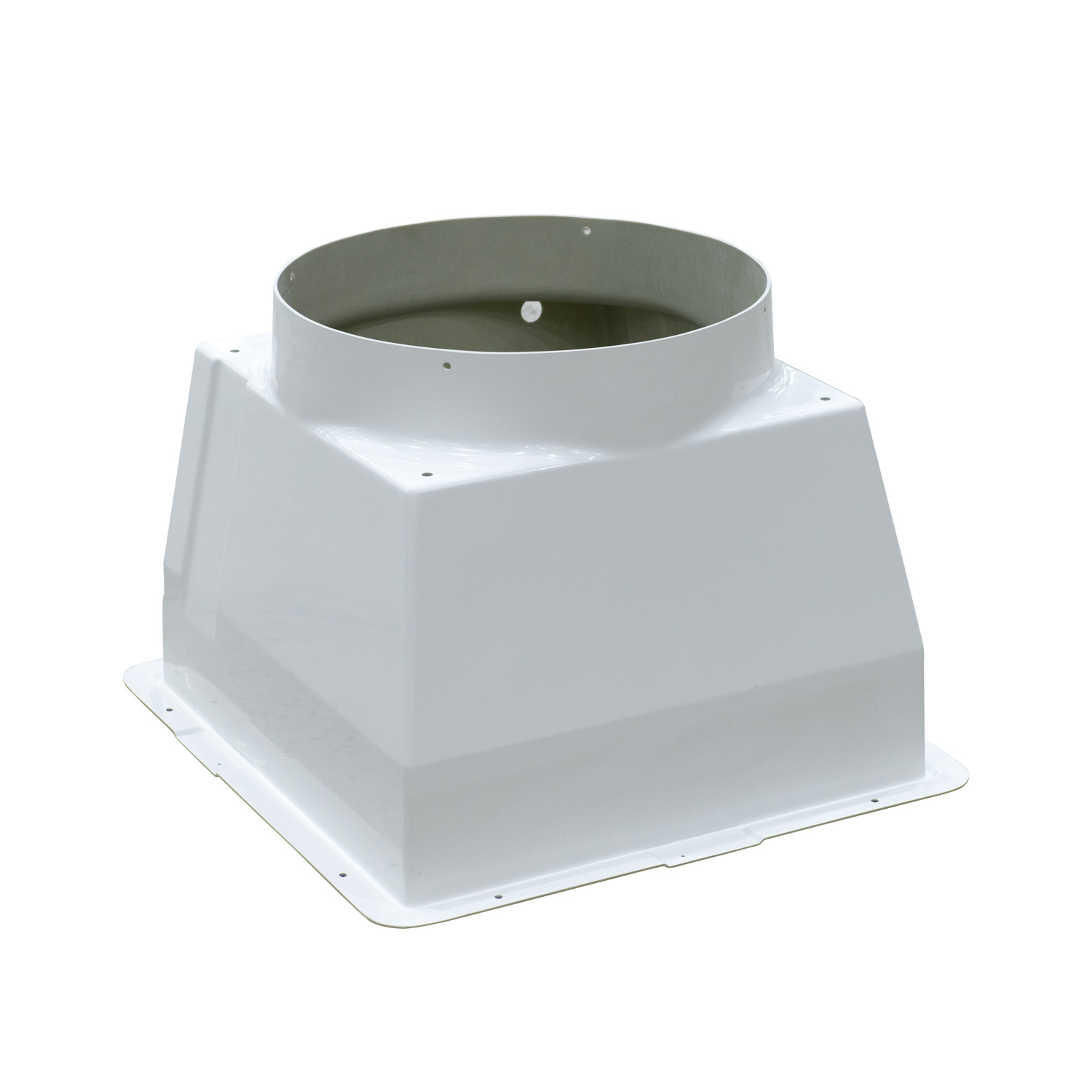

Professional R&D team, from development pipe design to finished products.

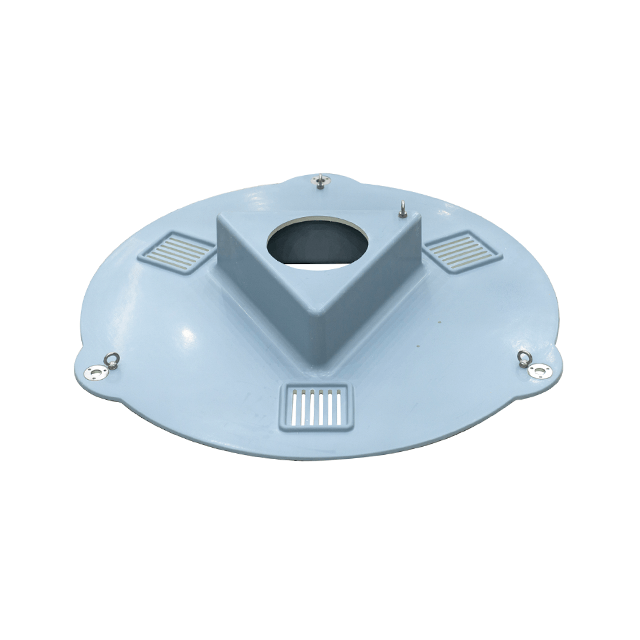

What is fiberglass molding?Have you ever wondered how lightweight yet durable materials are made? Fiberglass molding is a revolutionary process that combines strength and flexibility, playing a crucial role in many industries.

can you paint fiberglassHave you ever wondered if you can paint fiberglass? This versatile material is widely used in various industries, from automotive to marine applications. Understanding how to paint fiberglass can enhance its appearance and durability.

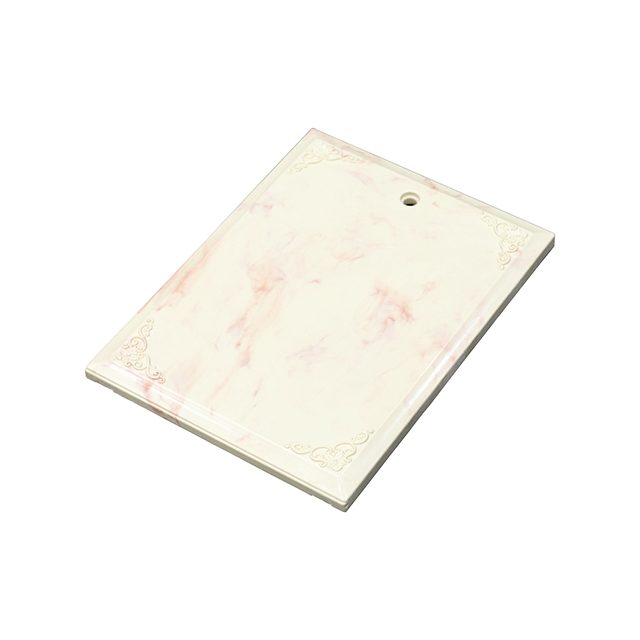

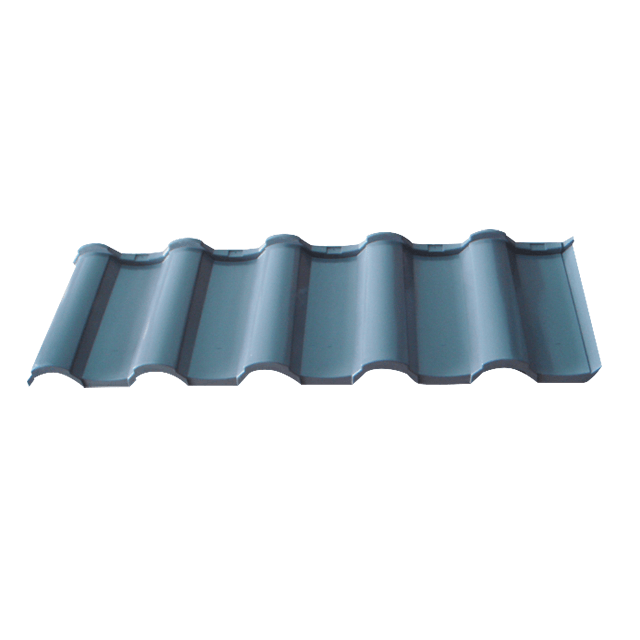

What is fiberglass used for in construction?Have you ever wondered how modern buildings withstand the test of time? Fiberglass plays a crucial role in construction, offering strength and versatility.

Is fibreglass plastic or glass?Is fiberglass just plastic or glass? This common question sparks curiosity about this versatile material.Fiberglass has a rich history and plays a crucial role in industries like automotive, construction, and aerospace.

What is fiberglass made of?IntroductionHave you ever wondered what makes fiberglass so strong yet lightweight? This versatile material combines glass fibers with resin for durability. Understanding what fiberglass is made of is essential for construction, automotive, and industrial projects. In this

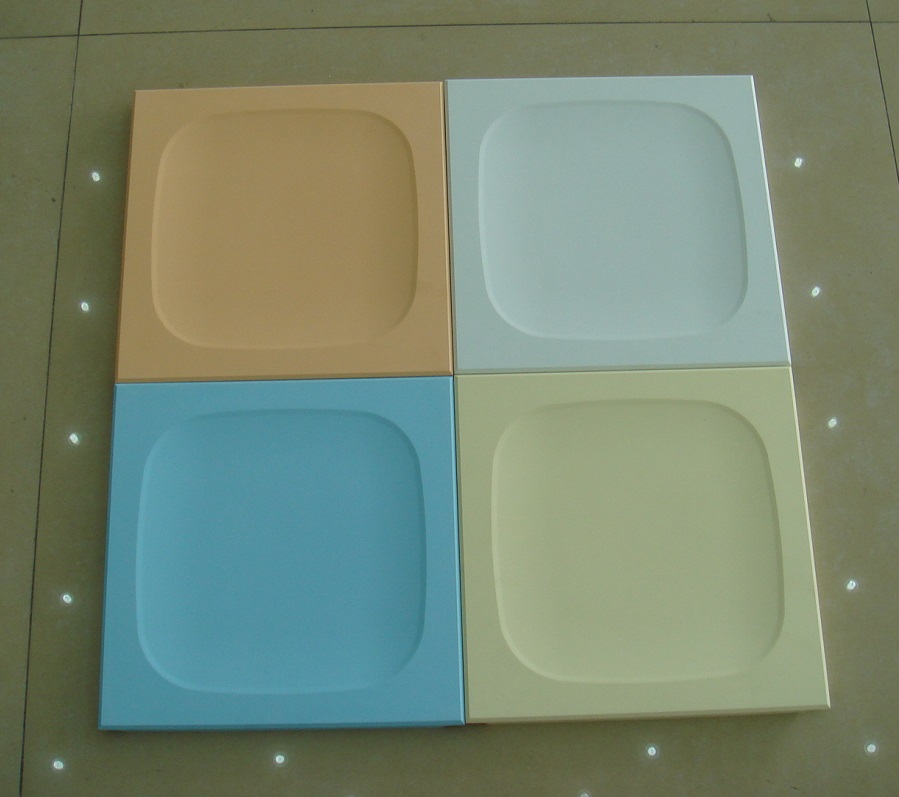

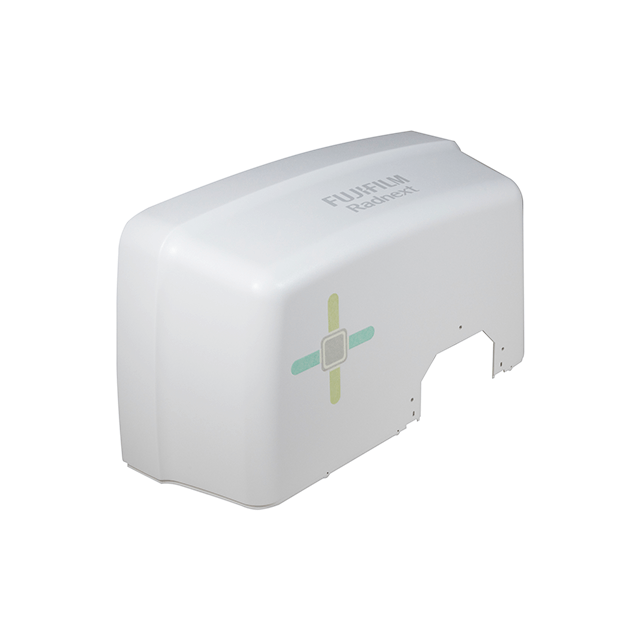

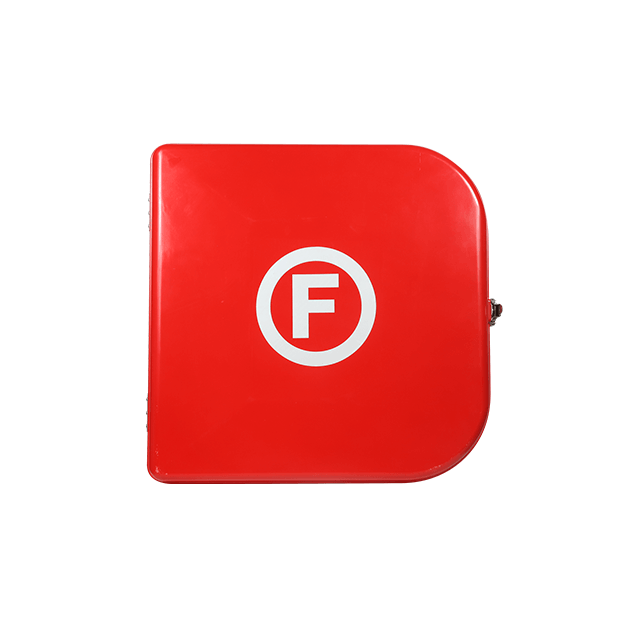

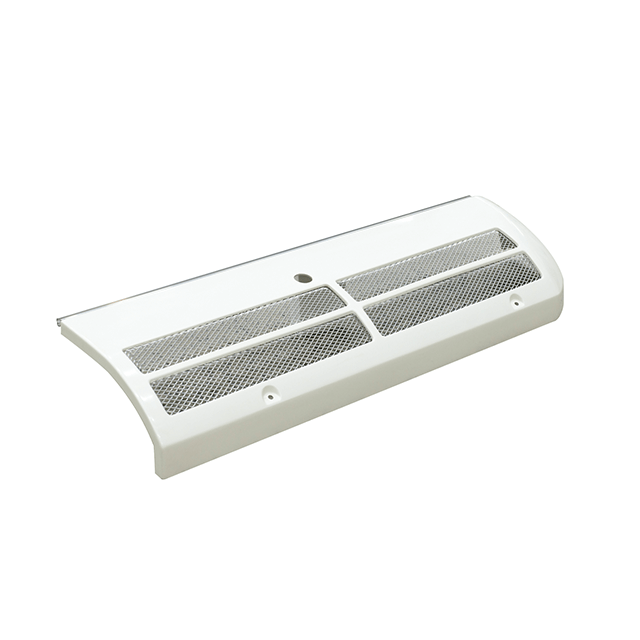

Fiberglass boxes provide strong, weather-resistant, and versatile storage for home, industrial, and commercial needs. Their lightweight, durable, and customizable design ensures efficient, long-lasting, and secure organization of tools, equipment, and other items across various environments.

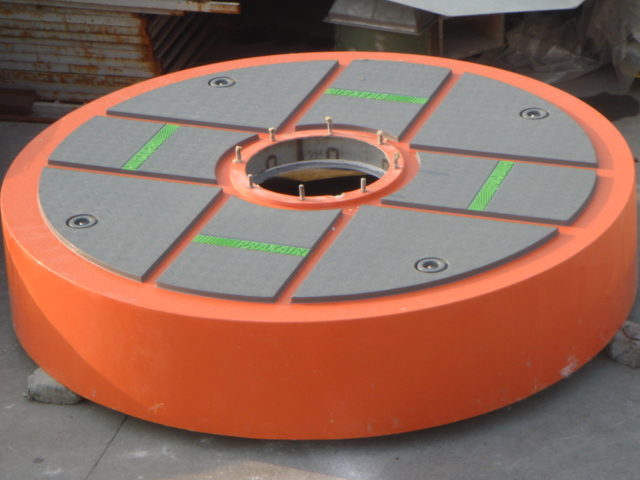

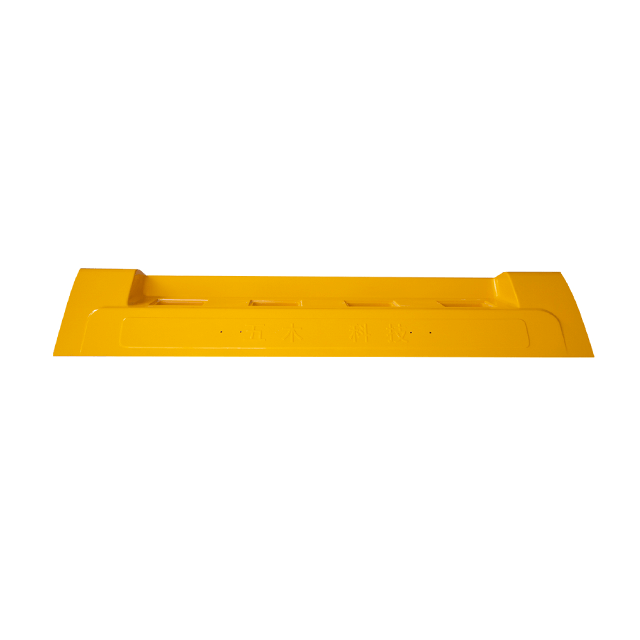

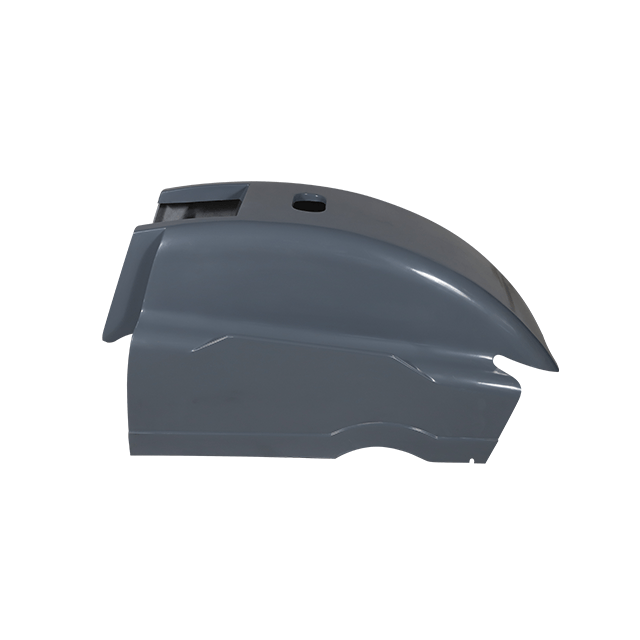

what is compression moldingCompression molding is a versatile manufacturing process that shapes materials by applying heat and pressure within a mold.

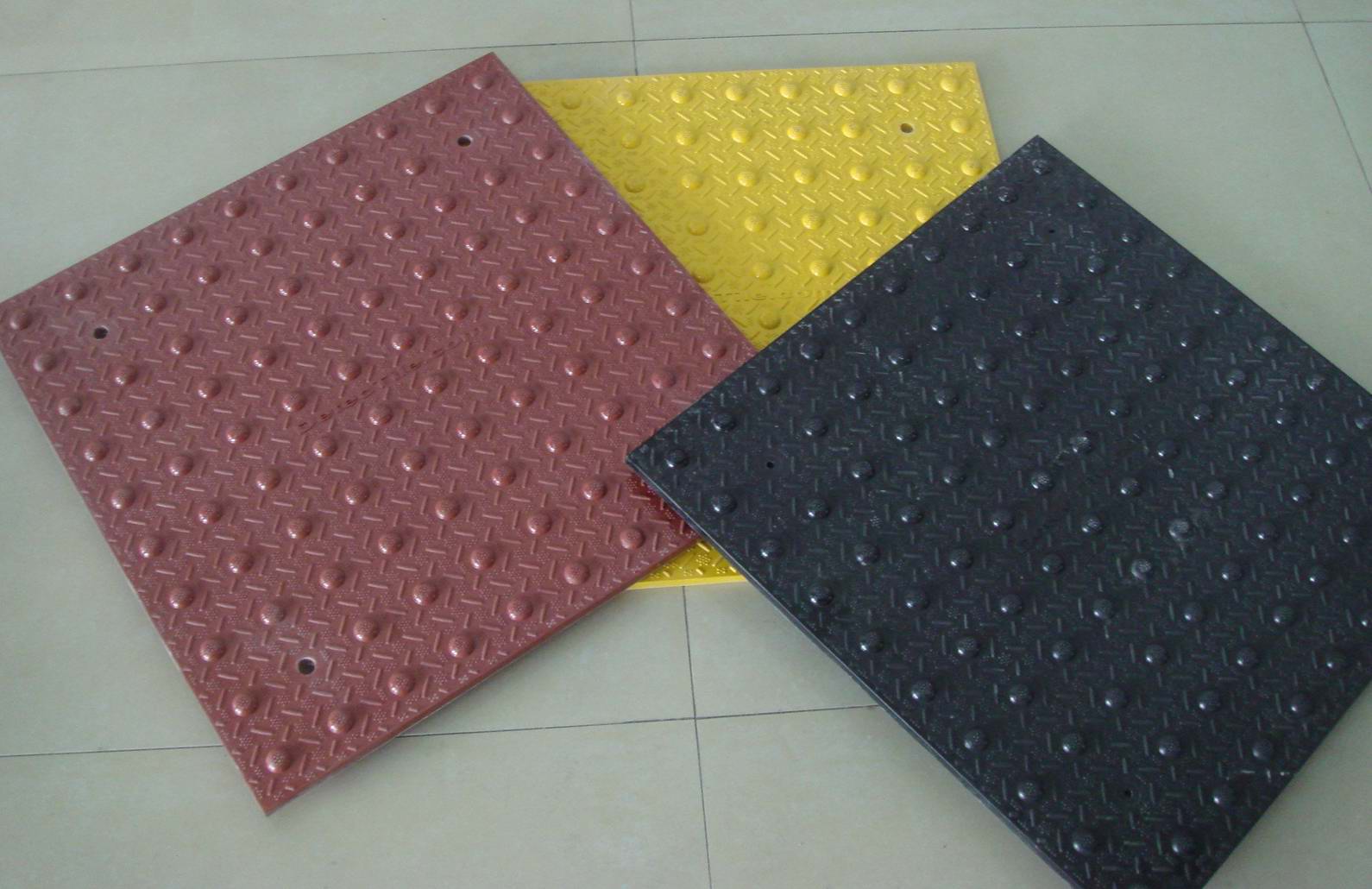

how to cut fiberglass reinforced panelsWhen it comes to cutting fiberglass reinforced panels (FRP), the right tools and techniques are essential for achieving clean, precise results while ensuring safety.