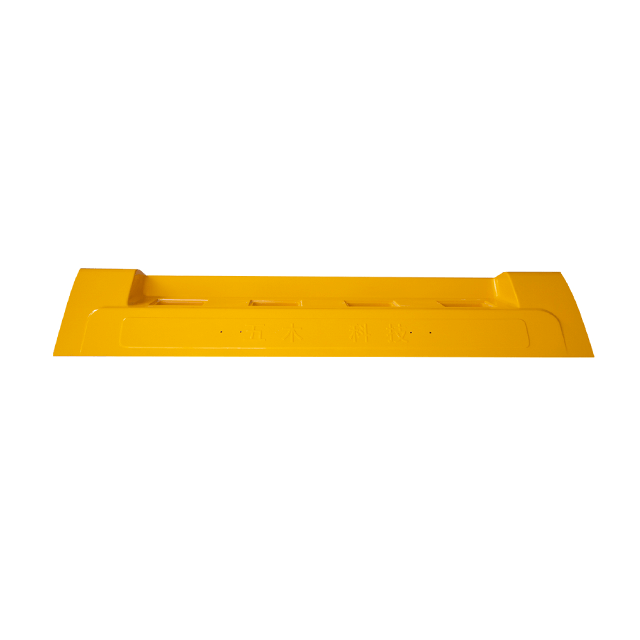

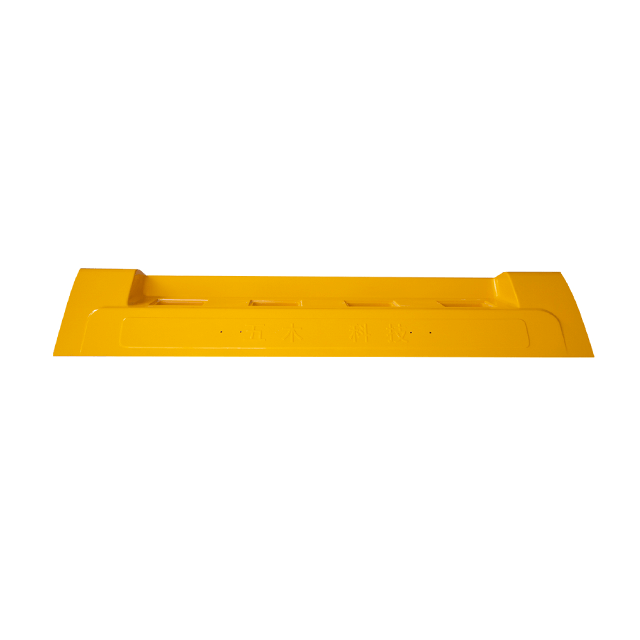

The Durable Hand Lamination FRP Shell for Equipment is a custom-engineered protective casing designed to shield industrial machinery, electronic enclosures, and precision instruments from harsh operating environments.

| Availability: | |

|---|---|

| Quantity: | |

Crafted using meticulous hand lamination techniques, this fiberglass-reinforced plastic (FRP) shell offers unmatched design flexibility, allowing for complex shapes and tailored dimensions that mass-produced alternatives cannot achieve. Its combination of lightweight construction, chemical resistance, and impact durability makes it indispensable in sectors ranging from manufacturing to renewable energy.

Custom Design Versatility

Hand lamination enables the creation of complex 3D geometries with precise cutouts for cables, vents, and access panels, accommodating unique equipment dimensions. Unlike compression-molded products, which require expensive tooling for each design, these shells offer cost-effective customization for small to medium production runs .

Enhanced Protective Properties

The multi-layered FRP structure, reinforced with high-strength glass fibers, achieves excellent chemical resistance against oils, solvents, and industrial cleaners. A protective gel coat finish adds UV stability, preventing color fading and material degradation in outdoor or brightly lit environments .

Lightweight and Impact-Resistant

Weighing 40% less than steel enclosures while maintaining comparable strength, the shell reduces equipment overall weight, simplifying transportation and installation. It withstands accidental impacts and vibrations, protecting sensitive internal components from damage during operation.

Industrial Machinery Enclosures

Used to house pumps, motors, and control systems in manufacturing plants, offering corrosion resistance in humid or chemical-exposed settings.

Renewable Energy Equipment

Protects inverters, sensors, and battery systems in solar farms and wind turbines, withstanding extreme temperatures and weather conditions.

Medical and Laboratory Equipment

Provides sterile, easy-to-clean casings for diagnostic machines and analytical instruments, meeting strict hygiene standards.

What thickness options are available for the FRP shell?

Standard thickness ranges from 3mm to 15mm, with custom thicker sections available for high-impact applications.

Can the shell be colored or finished to match equipment aesthetics?

Yes, the gel coat is available in custom RAL colors, with matte, gloss, or textured finishes to meet branding or operational requirements.

Is the shell suitable for food-grade applications?

Absolutely, when specified with FDA-approved resin, it meets food safety standards for equipment in processing facilities.

What is the lead time for custom orders?

Typically 2–4 weeks for prototypes and 4–6 weeks for production runs, depending on design complexity and order volume.

Crafted using meticulous hand lamination techniques, this fiberglass-reinforced plastic (FRP) shell offers unmatched design flexibility, allowing for complex shapes and tailored dimensions that mass-produced alternatives cannot achieve. Its combination of lightweight construction, chemical resistance, and impact durability makes it indispensable in sectors ranging from manufacturing to renewable energy.

Custom Design Versatility

Hand lamination enables the creation of complex 3D geometries with precise cutouts for cables, vents, and access panels, accommodating unique equipment dimensions. Unlike compression-molded products, which require expensive tooling for each design, these shells offer cost-effective customization for small to medium production runs .

Enhanced Protective Properties

The multi-layered FRP structure, reinforced with high-strength glass fibers, achieves excellent chemical resistance against oils, solvents, and industrial cleaners. A protective gel coat finish adds UV stability, preventing color fading and material degradation in outdoor or brightly lit environments .

Lightweight and Impact-Resistant

Weighing 40% less than steel enclosures while maintaining comparable strength, the shell reduces equipment overall weight, simplifying transportation and installation. It withstands accidental impacts and vibrations, protecting sensitive internal components from damage during operation.

Industrial Machinery Enclosures

Used to house pumps, motors, and control systems in manufacturing plants, offering corrosion resistance in humid or chemical-exposed settings.

Renewable Energy Equipment

Protects inverters, sensors, and battery systems in solar farms and wind turbines, withstanding extreme temperatures and weather conditions.

Medical and Laboratory Equipment

Provides sterile, easy-to-clean casings for diagnostic machines and analytical instruments, meeting strict hygiene standards.

What thickness options are available for the FRP shell?

Standard thickness ranges from 3mm to 15mm, with custom thicker sections available for high-impact applications.

Can the shell be colored or finished to match equipment aesthetics?

Yes, the gel coat is available in custom RAL colors, with matte, gloss, or textured finishes to meet branding or operational requirements.

Is the shell suitable for food-grade applications?

Absolutely, when specified with FDA-approved resin, it meets food safety standards for equipment in processing facilities.

What is the lead time for custom orders?

Typically 2–4 weeks for prototypes and 4–6 weeks for production runs, depending on design complexity and order volume.

+86 13913647707 / 13915651436